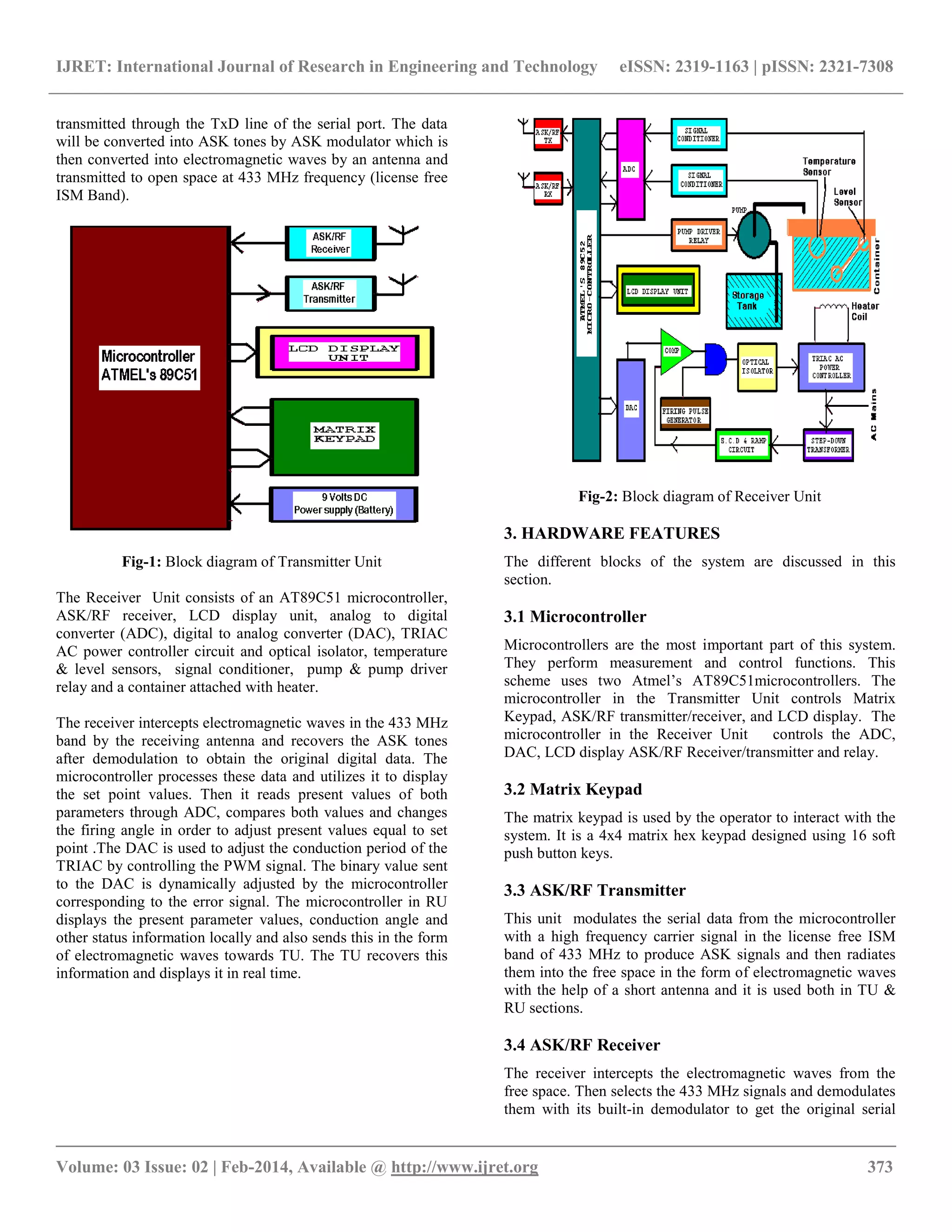

1. The document describes a low-cost wireless embedded system for monitoring and controlling multiple parameters like temperature and fluid level from a remote site. 2. The system uses a microcontroller, RF transmitter and receiver, sensors and actuators to monitor and control the temperature of a heater and fluid level in a tank. 3. Experimental results show the system can accurately control the temperature and fluid level based on setpoint values by adjusting the power to the heater and a pump motor.

![IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308 __________________________________________________________________________________________ Volume: 03 Issue: 02 | Feb-2014, Available @ http://www.ijret.org 372 A LOW COST SHORT RANGE WIRELESS EMBEDDED SYSTEM FOR MULTIPLE PARAMETER CONTROL Sudhindra F1 , Annarao. S. J2 , Vani R. M3 , P.V. Hungund4 1 Technical Officer-I, U.S.I.C, Gulbarga University, Gulbarga, Karnataka, India 2 Head, Dept. of Electronics, HKE’s Women’s Polytechnic, Gulbarga, Karnataka, India 3 Head, USIC, Gulbarga University, Gulbarga, Karnataka, India 4 Professor, Dept. of Applied Electronics, Gulbarga University, Gulbarga, Karnataka, India Abstract It is well established fact that the process atomization offers the advantages like high accuracy, power saving, manpower saving, reduction in wastage, high & efficient production volumes. In the modern industries precise monitoring, & controlling of temperatures & fluid level of various chemicals in storage tanks at various places is an essential requirement. This paper describes the development of Wireless Embedded System by using Atmel’s 89C51 microcontroller for monitoring & control of process parameters from remote site .The system utilizes ASK transmitter & receiver for transmission and reception of reference values i.e., temperature and fluid levels from transmitter to receiver. Interaction with transmitter is done through matrix keypad. A TRIAC AC power controller circuit is used in the receiver which controls the flow of power to the heater. The fluid level is maintained by a water feed pump .User friendly Software is developed using 8051’s Assembly language to control the transmitter and receiver units. Keywords: ASK/RF transceiver, Temperature sensor, Triac, Fluid level sensor and Microcontroller etc… ----------------------------------------------------------------------***------------------------------------------------------------------------ 1. INTRODUCTION Microcontrollers have been used in the recent past in various industrial applications and R & D for controlling and monitoring various parameters. Automated monitoring and controlling of various process parameters, through the use of electronic techniques are in use since a long time. Such systems have become essential and it has always yielded better results over their manual counterparts. However such systems suffer from some disadvantages like the overshoots and undershoot in the controlled parameters, since they use relay type control and they allow the monitoring and control of process parameters only from close vicinity. Besides to adjust set points and periodic recording of parameters, an operator is required. Microcontroller applications in dedicated system assumed an important place in engineering, especially the large scale industries. With the advancement in techniques for control systems and additional requirement of miniaturization, microcontrollers have become the most suitable components. We find such application [1], in which microcontroller based temperature indicator & controller was developed which can be used in process industry for monitoring & control of temperature. In the other application A. Rajendran et al, have developed a data acquisition system with AT89C52 microcontroller & PID algorithm [2]. In another work J. Jayapandian et al, has developed single chip embedded temperature controller and they have used Programmable System on Single Chip (PSOC). The LabVIEW is used to implement the control program.[3], Our proposed work aims at designing a wireless embedded system for multiple parameter monitoring and control using thyristors and microcontrollers. An attempt is made to design hardware and software for a compact, reliable, and low cost system to achieve remote process automation. In this system process automation is implemented for the temperature and fluid level measurement. However, any other physical parameters like pressure, flow, illumination, DC motor speed, AC motor speed, conveyer belt speed etc can also be easily implemented. 2. SYSTEM DESCRIPTION The block diagram of the Wireless Embedded System for multiple parameter control is shown fig.1 and fig. 2. The system hardware consists of two sections i.e. Transmitter Unit (TU) and Receiver Unit (RU). The Transmitter Unit consists of an AT89C51 microcontroller, 4X4 matrix keyboard, 16 X 2 LCD display unit, ASK/RF transmitter, ASK/RF receiver, buzzer. The microcontroller continuously scans the keypad and checks for the key pressings. If any key is pressed then it sends the information to LCD display unit and to the SBUF register which will be](https://image.slidesharecdn.com/alowcostshortrangewirelessembeddedsystemformultipleparametercontrol-140811022605-phpapp01/75/A-low-cost-short-range-wireless-embedded-system-for-multiple-parameter-control-1-2048.jpg)

![IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308 __________________________________________________________________________________________ Volume: 03 Issue: 02 | Feb-2014, Available @ http://www.ijret.org 376 to reference value (here it is 60% of the container), the relay turns off the pump motor. 0 10 20 30 40 50 60 1 2 3 4 5 6 7 8 Time in seconds Temperatureindeg.c set points current values of temperature Scale : x axis = 1 x 10 Fig-5: Temperature VS Time in Sec It has been observed that the designed system works properly as per the control logic. From the above discussions it is clear that the system is automatic, wireless, real time monitoring and does the control of parameters within the range of 300ft even in the hazard industrial environment. 0 10 20 30 40 50 60 70 1 2 3 4 5 6 7 8 Time in seconds Percentageoffluid set point % of fluid level under motor off position Scale : x axis = 1 x 10 Increase in % of fluid level under motor On position Fig-6: % of Fluid VS Time in Sec CONCLUSIONS The wireless embedded system for multiple parameter control using Atmel‟s 89C51 microcontroller is designed and developed successfully in the laboratory. The developed system is simple, low cost, and suitable for multiple process parameter control. This design permits the user to adjust process parameters from the remote transmitter unit. As it is a real time system it will display both reference and current values of the parameters on the LCD of transmitter continuously. The developed system also issues warning signals to the operator within the vicinity of transmitter so that he can interact with the system. The system is wireless and the distance between TU & RU can be up to 300ft. The system with minor modifications can be used for various types of process parameter control and suitable for Industrial applications where remote control is necessary. REFERENCES [1]. R.G. Jamkar and R.H. Chile “Microcontroller based Temperature Indicator and Controller”, J. Instrum. Soc . India 34(3) 180-186, Sept-2004. [2]. A.Rajendran and P. Neelamegam “Design of AT89C52 Microcontroller based system for the measurement of Temperature and control”, J. Instrum. Soc , India 35(I)99-105, March-2005. [3]. J. Jayapandian and Usha Rani Ravi “An Embedded Single Chip Temperature Controller Design” J. Instrum, Soc. India 38(2) 132-136, June-2008. [4]. Kenneth J. Ayala, “The 8051 Microcontroller – Architecture , Programming and Applications”, 2nd Edition , Penaram International Publishing ( India) , 1996. [5]. Ramakant Gaikwad, “Op-amps and linear integrated circuits”, 3rd Edition Prentice- Hall of India Pvt. Ltd, New Delhi. [6]. Muhammad Ali Mazidi, Janice Gillispie and Rolin D. McKinlay “The 8051 Microcontroller and Embedded Systems using Assembly and „C‟., Prentice – Hall of India, New Delhi, 2nd Edition . BIOGRAPHIES Sudhindra F. Received his B.E (E&CE) from Gulbarga University, Gulbarga and Master‟s degree from KSOU , Mysore. He is working as Technical Officer-I in University Science Instrumentation Centre, Gulbarga University, Gulbarga since 1995. He has completed his M.Phil from Gulbarga University, Gulbarga. He has attended many seminars, workshops and conferences. His areas of interest are digital electronics, Embedded Controllers and Wireless communication. He has serviced and repaired more than 500 laboratory instruments. Annarao.S.J. received his B.Tech (E&CE) from Guru Ghasidas University, Bilaspur Chattisgarh and pursuing Master‟s degree from KSOU, Mysore. He is working as Head of Department in Electronics and Communication Engineering Department of HKE Society‟s women‟s polytechnic, Gulbarga. He has attended many seminars, workshops and conferences. His areas of interest are embedded systems, Biomedical, RFID, GSM, GPS, Wireless communication and Computers. He has guided more than 500 live projects for diploma, BE and M.Tech students. Vani R. M. received her B.E. in Electrical and Electronics from the B.I.ET., Davanagere and M.Tech in Industrial Electronics from S.J.C.E., Mysore, Karnataka. She has received her Ph.D in Applied Electronics from Gulbarga University, Gulbarga, India, in year](https://image.slidesharecdn.com/alowcostshortrangewirelessembeddedsystemformultipleparametercontrol-140811022605-phpapp01/75/A-low-cost-short-range-wireless-embedded-system-for-multiple-parameter-control-5-2048.jpg)