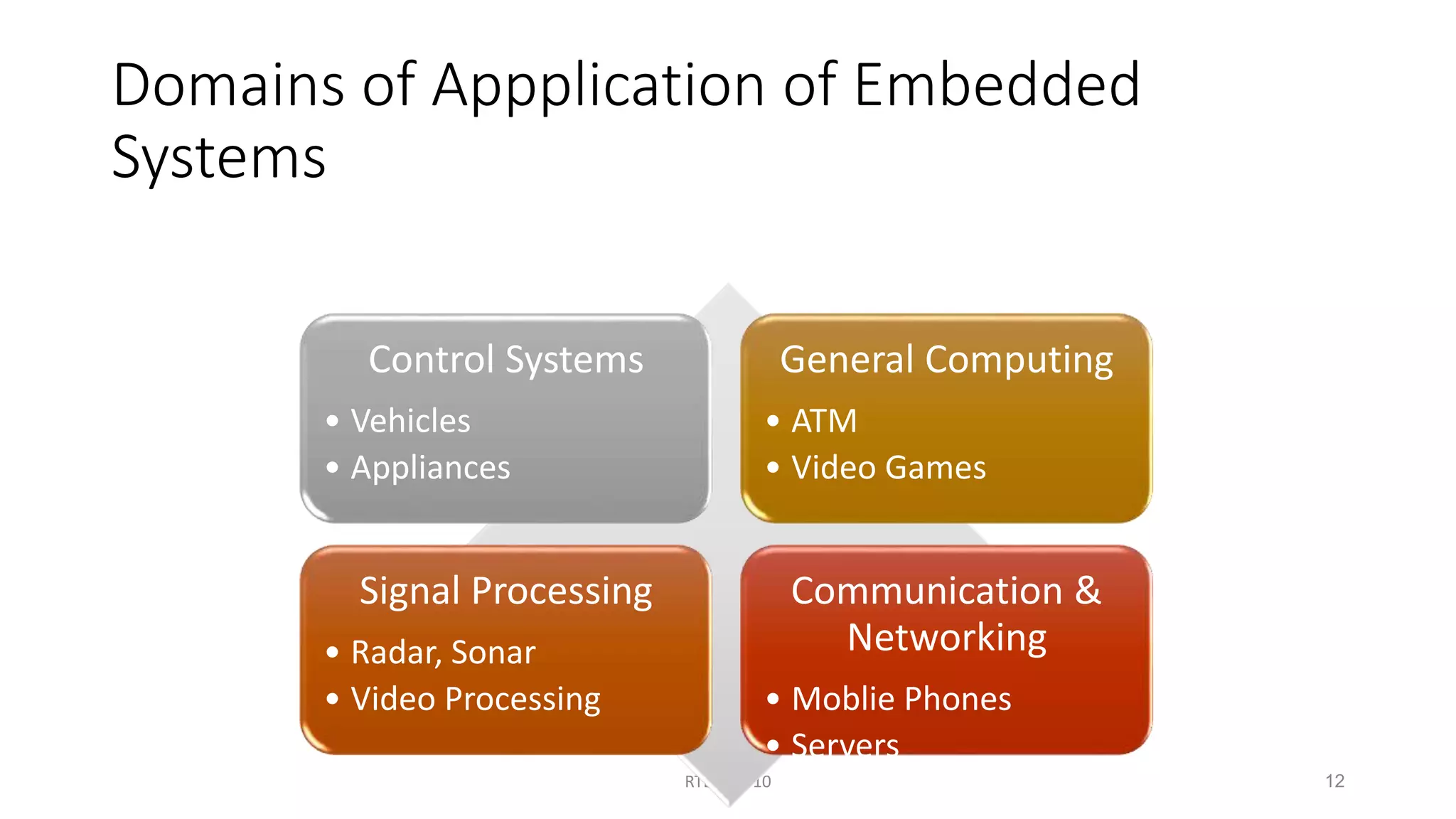

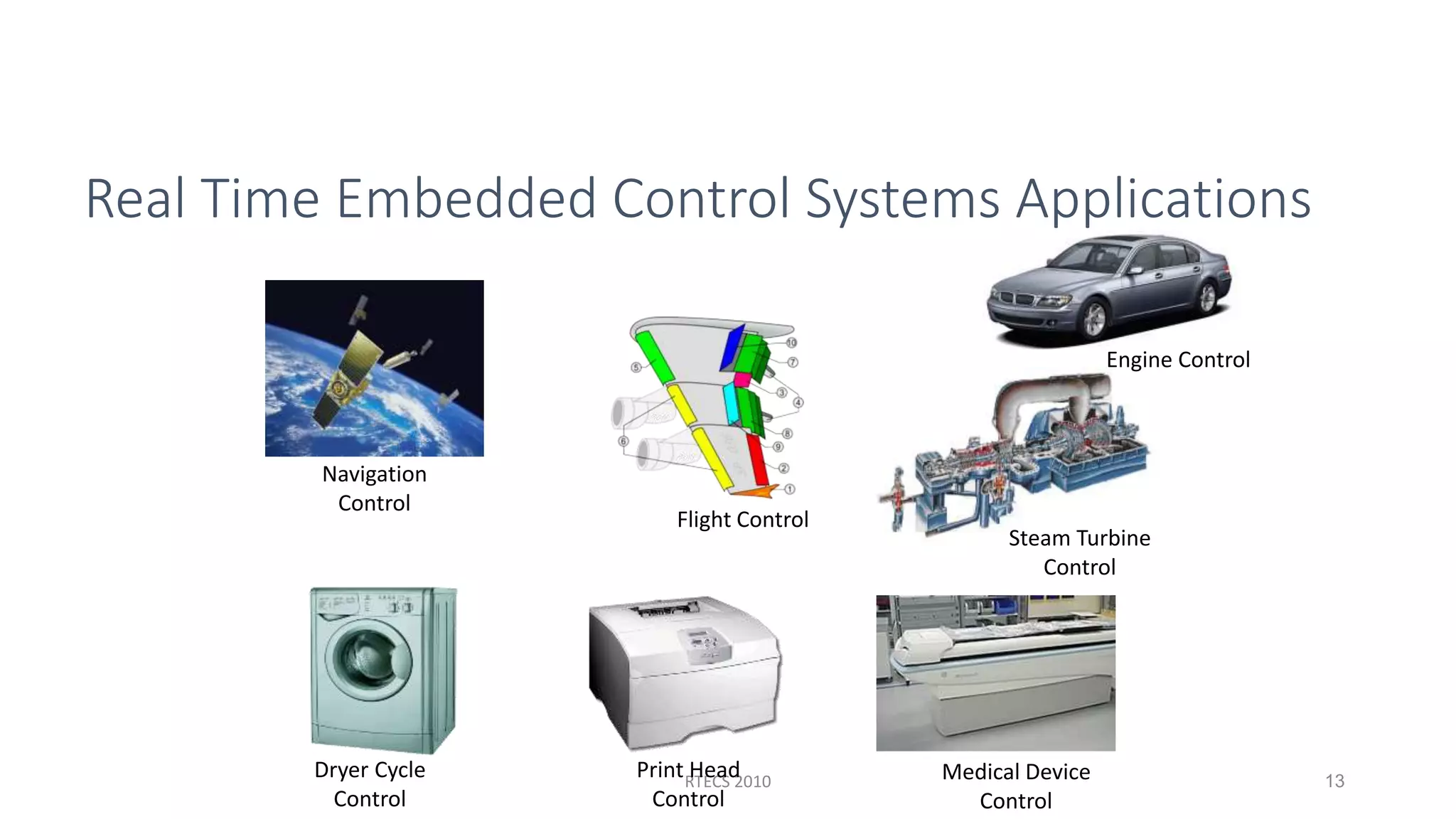

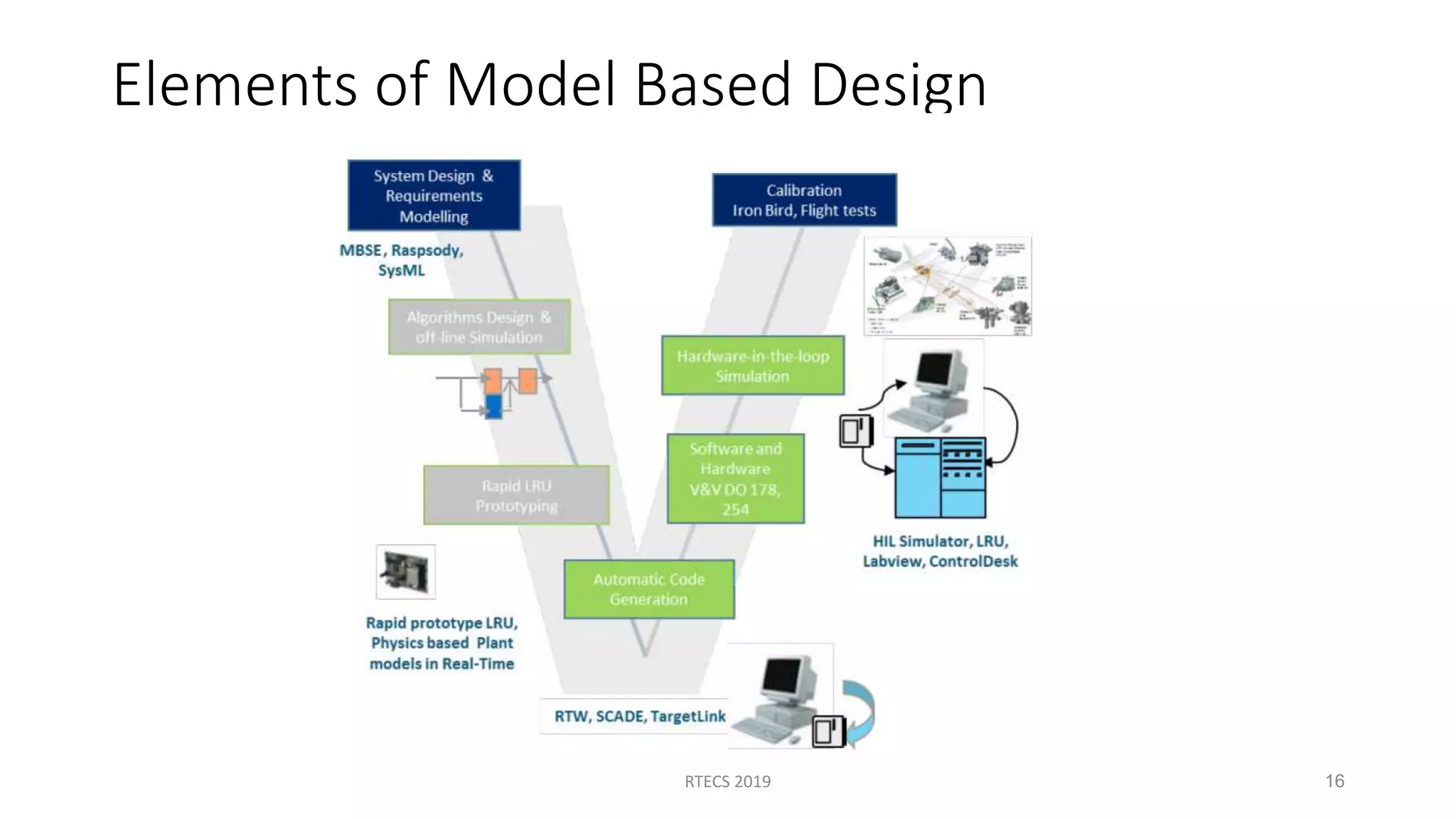

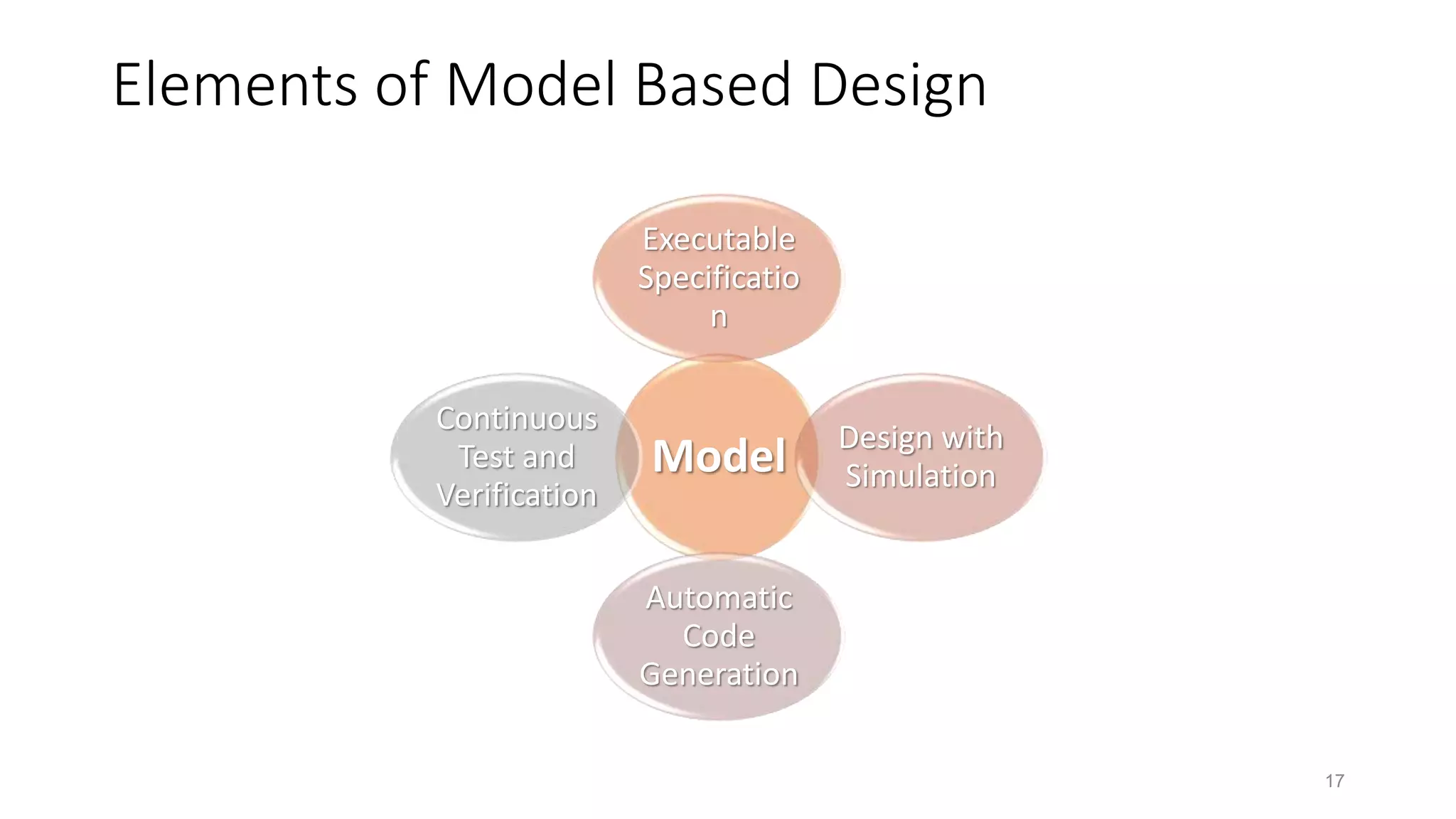

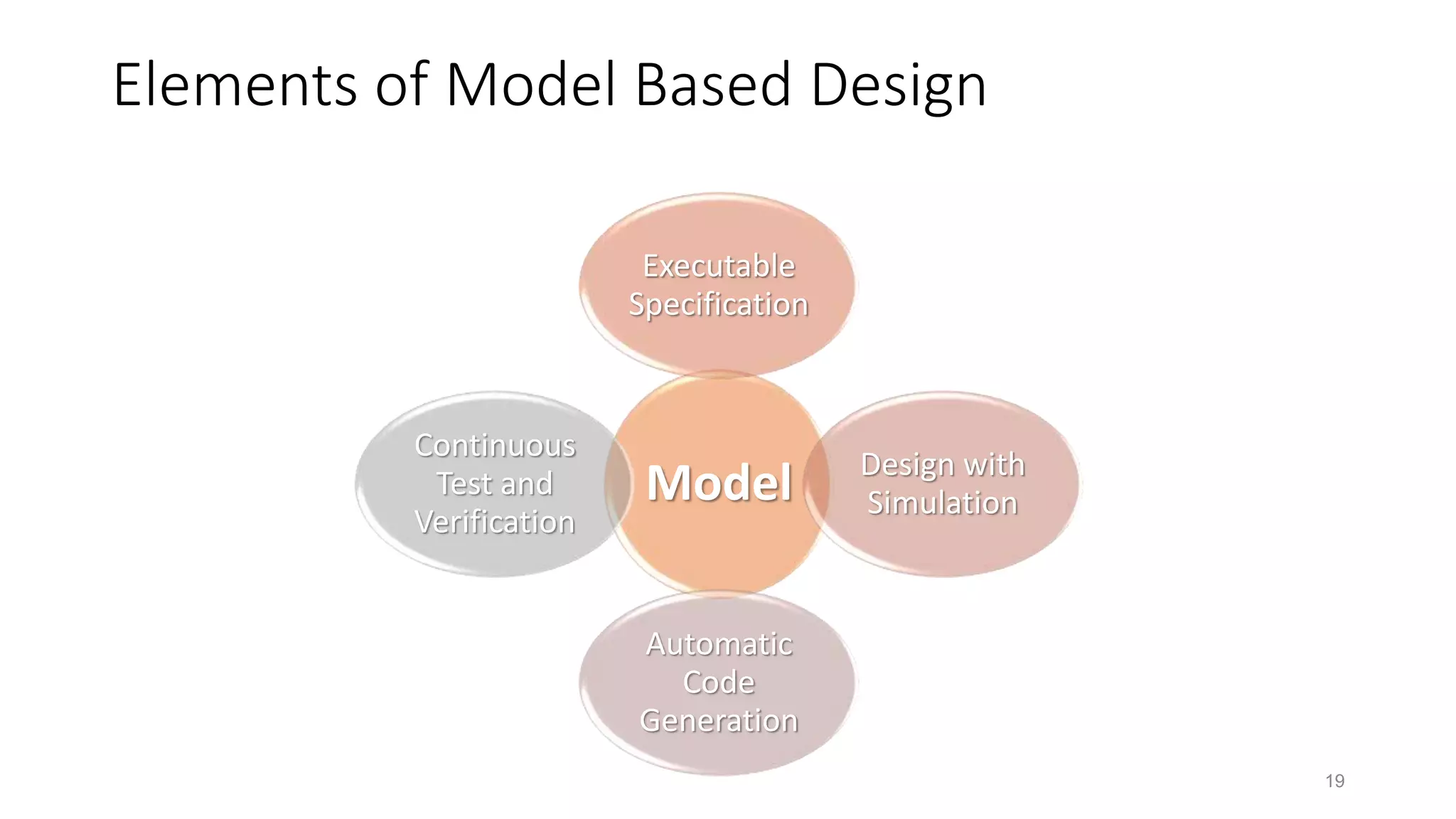

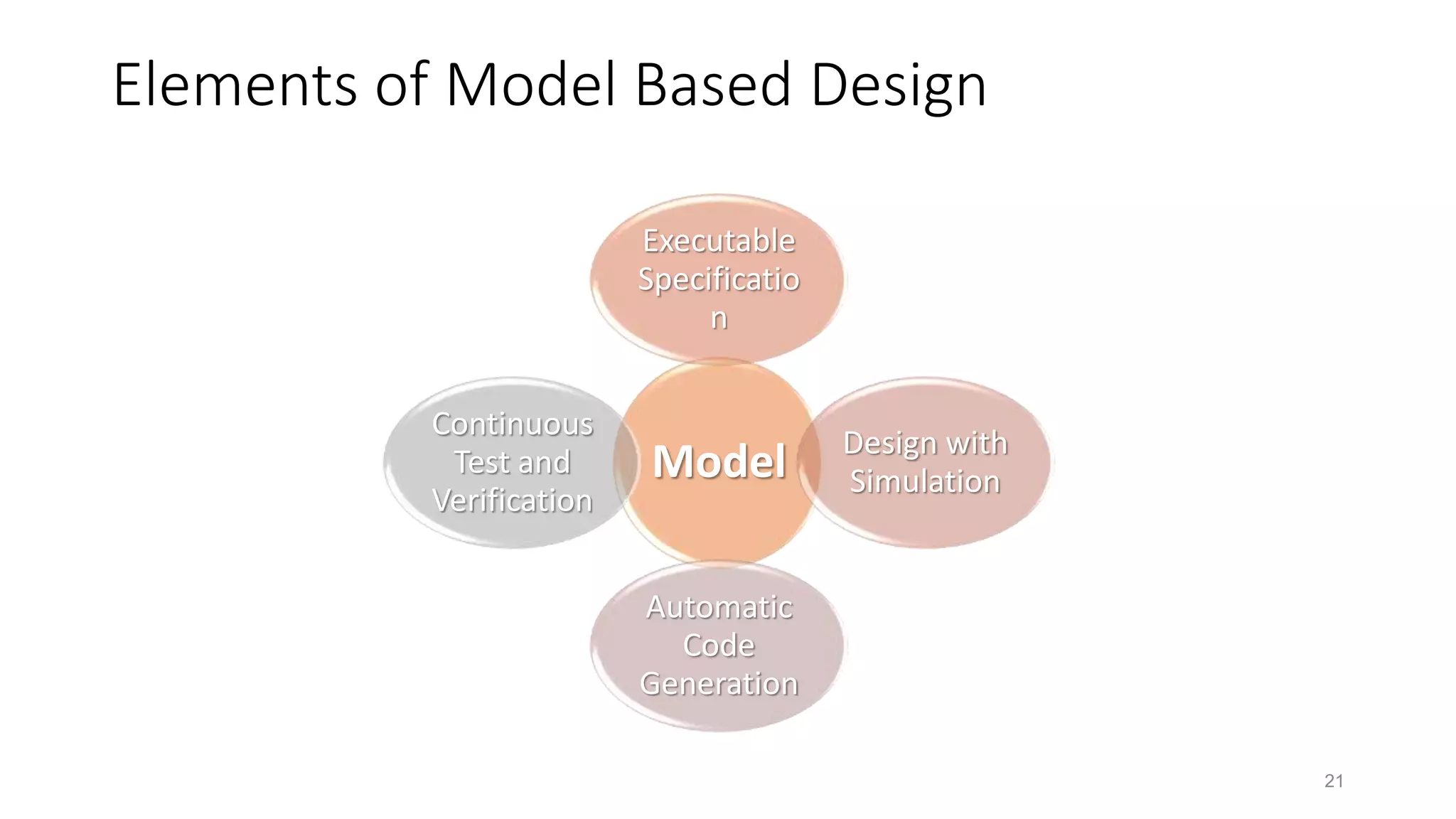

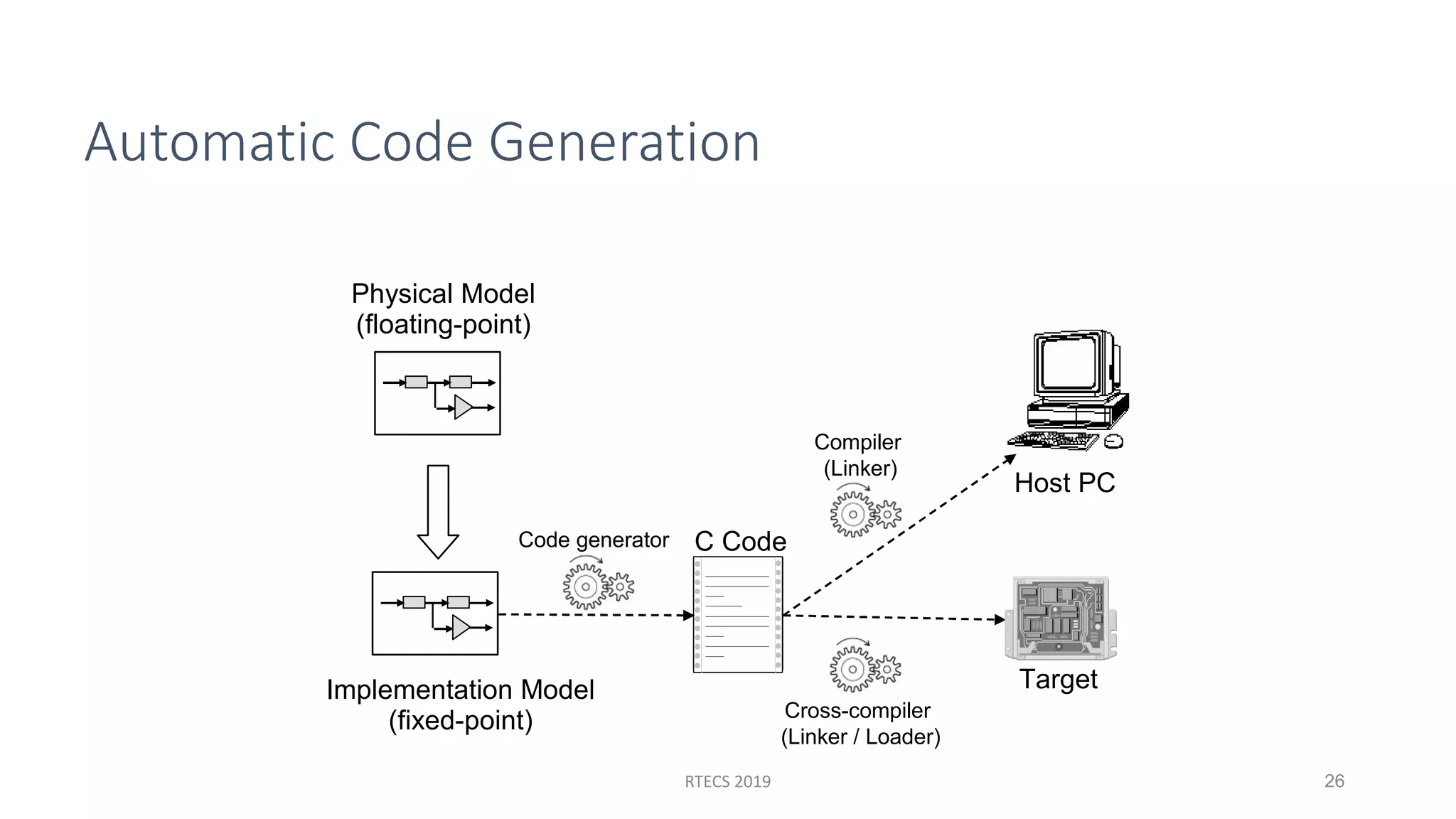

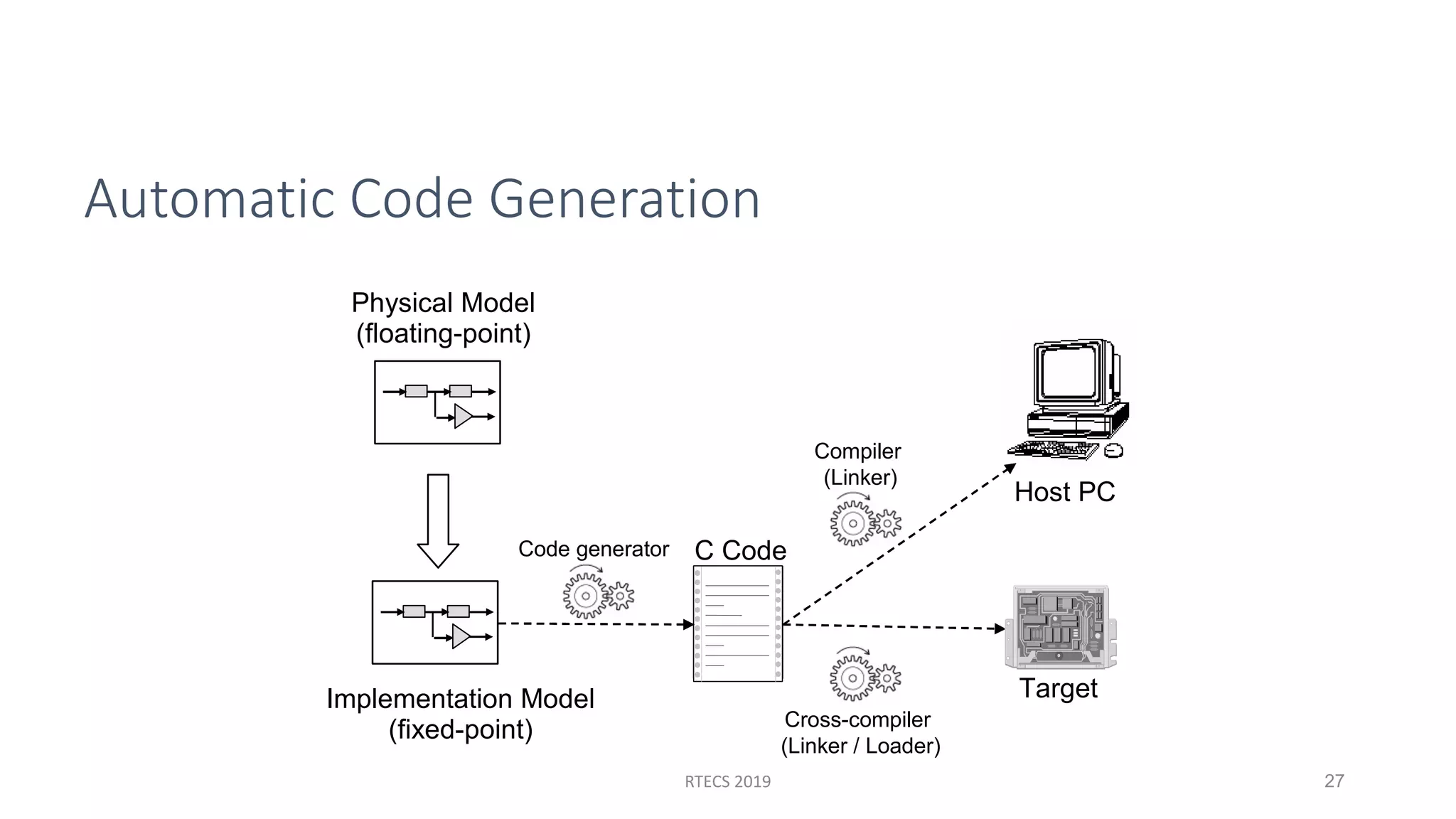

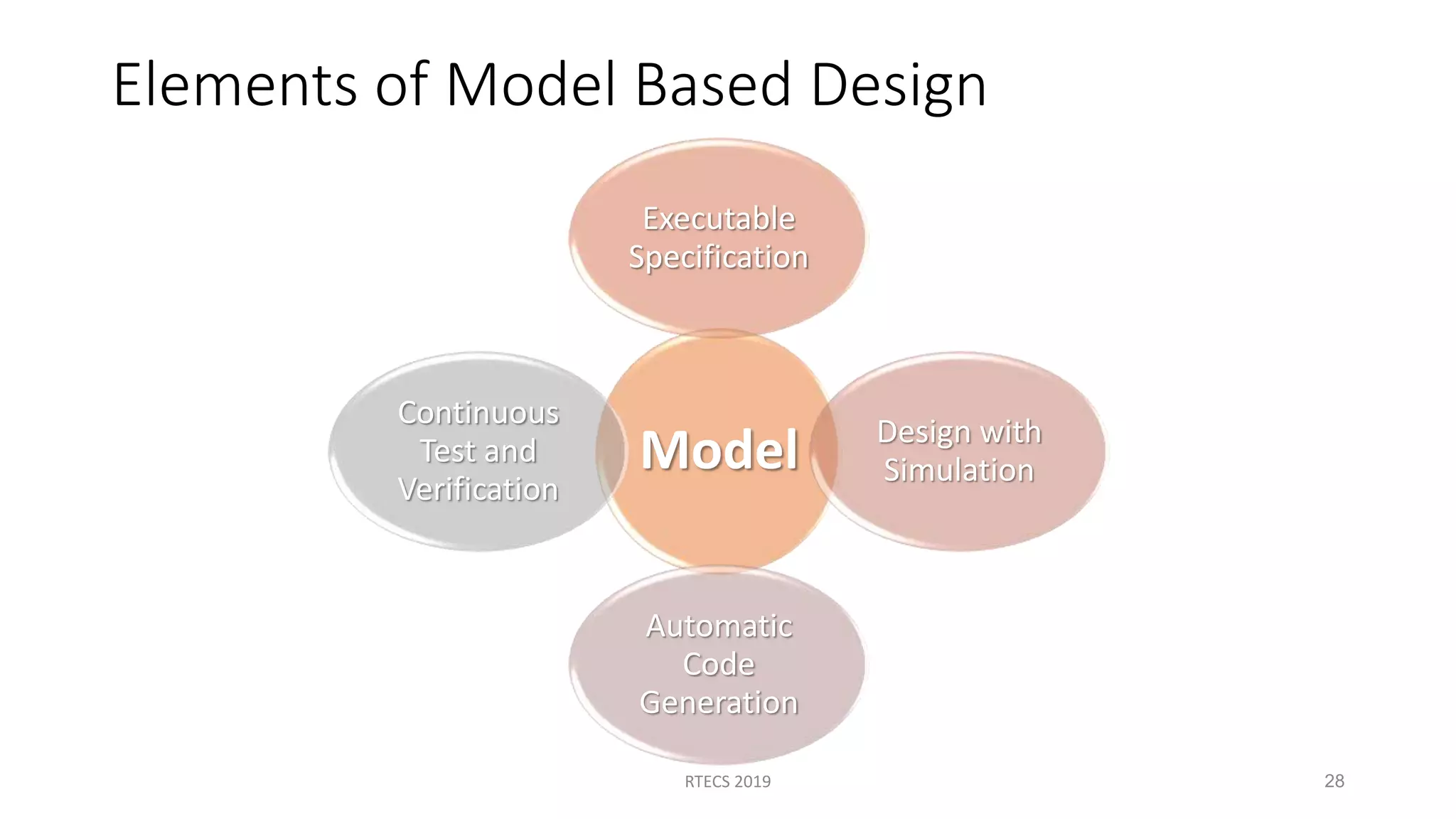

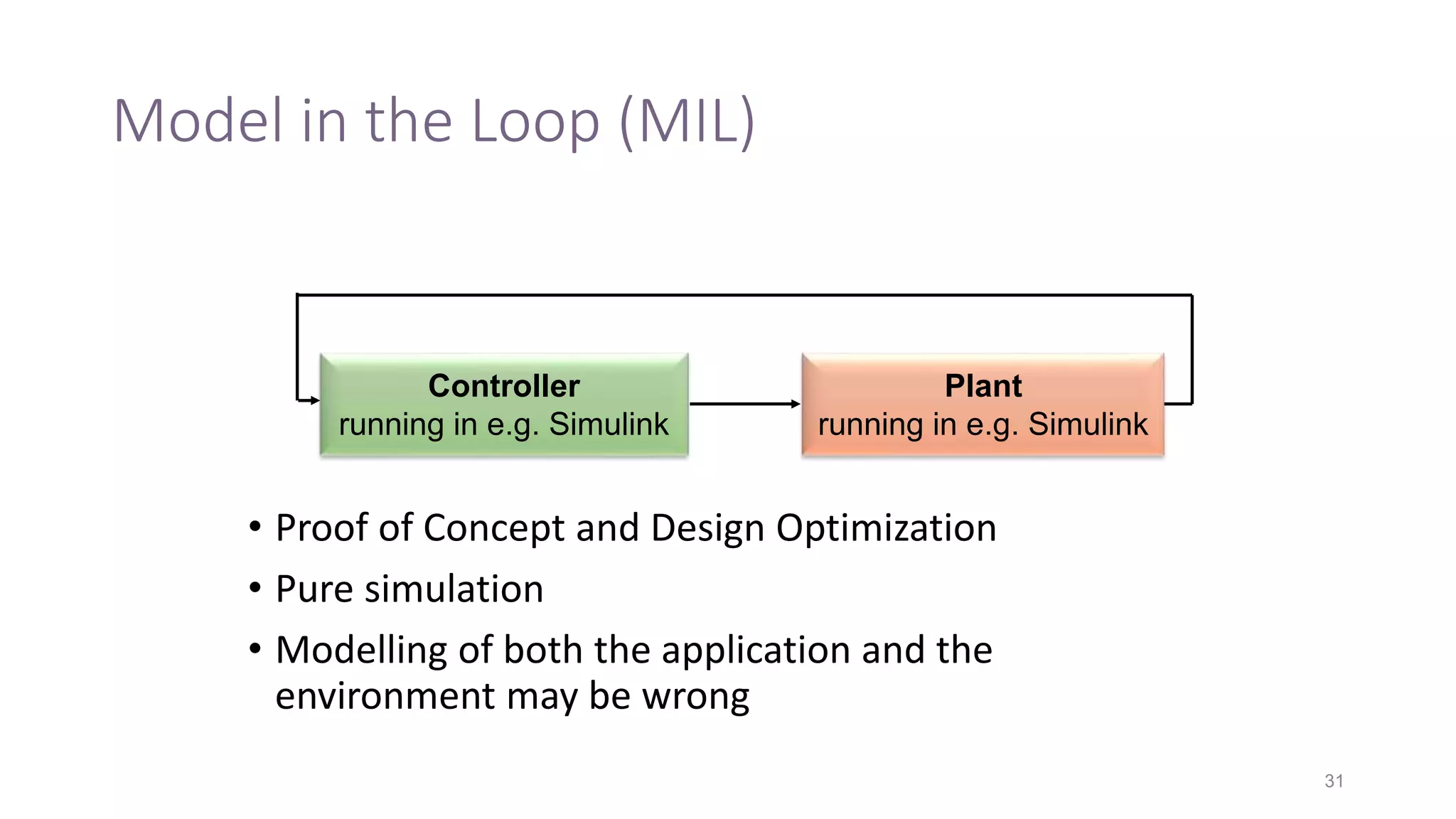

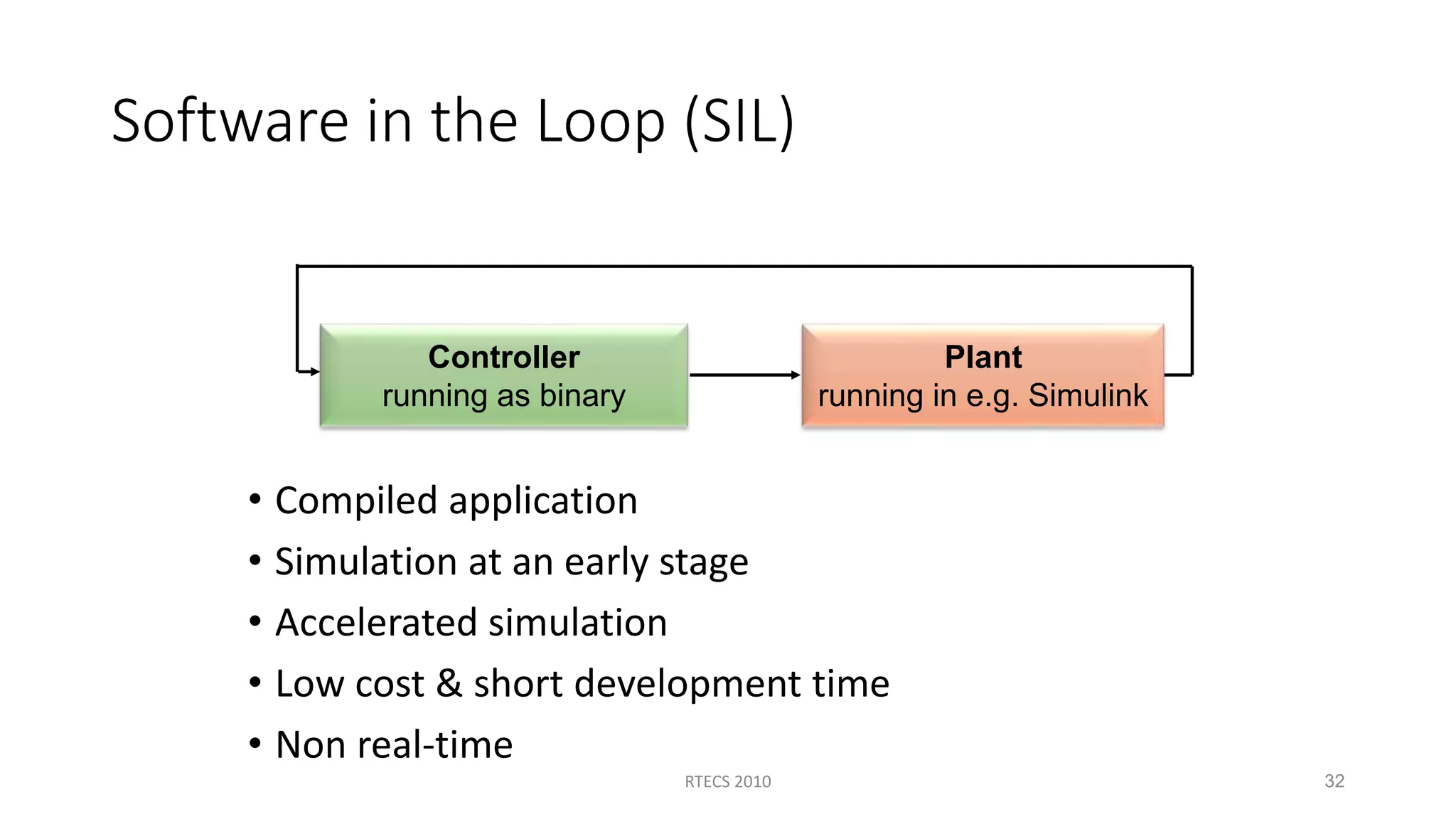

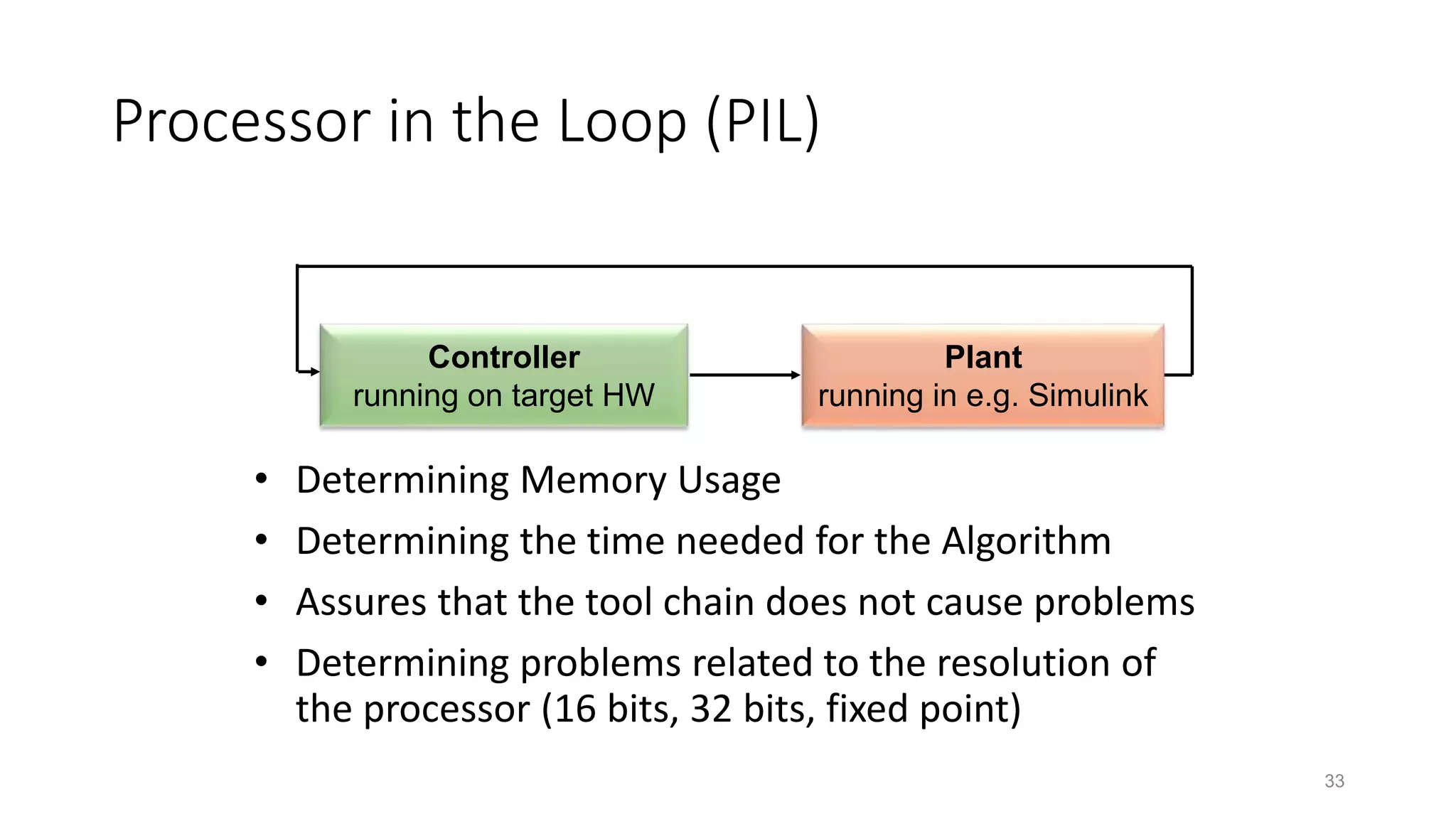

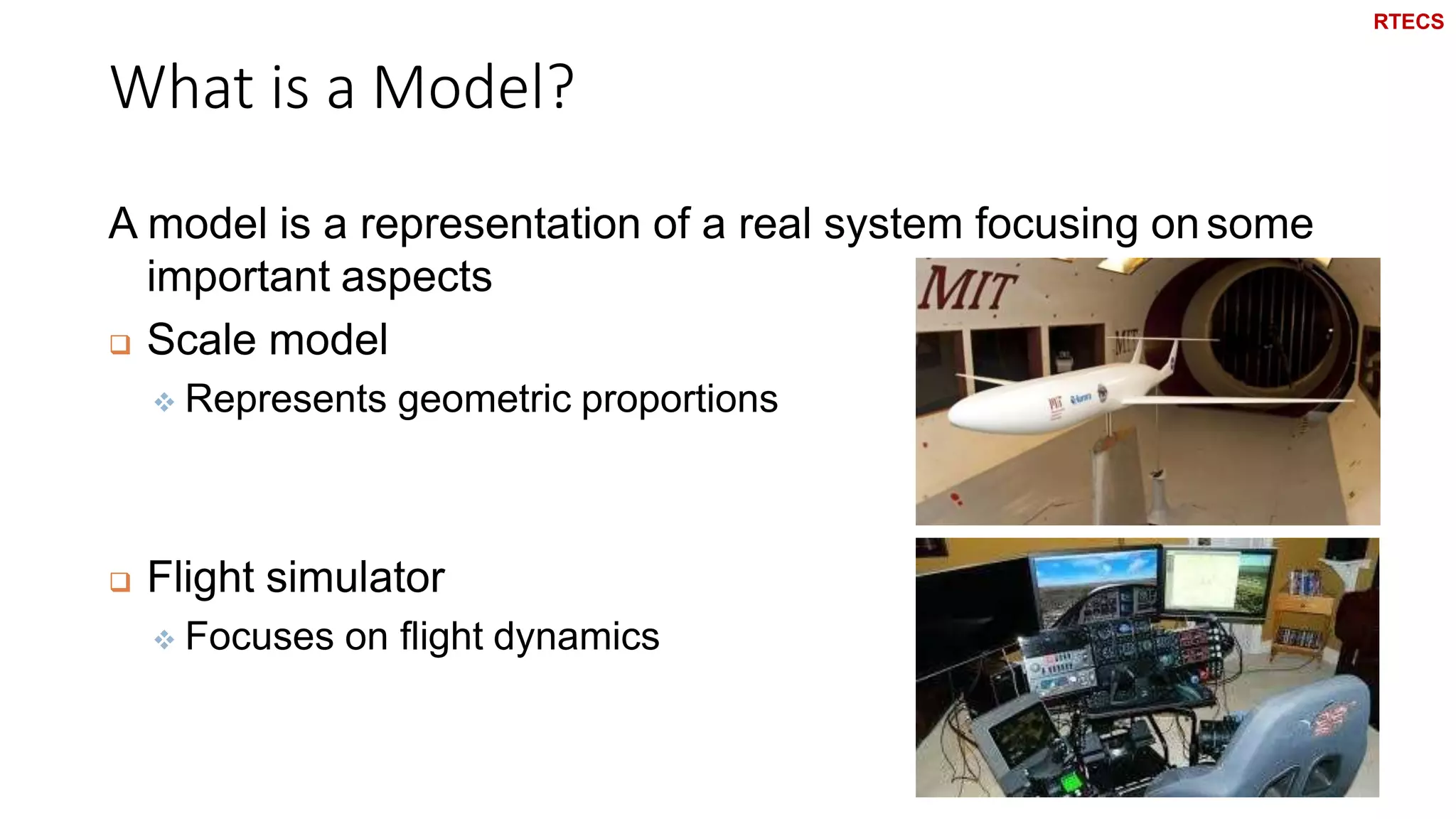

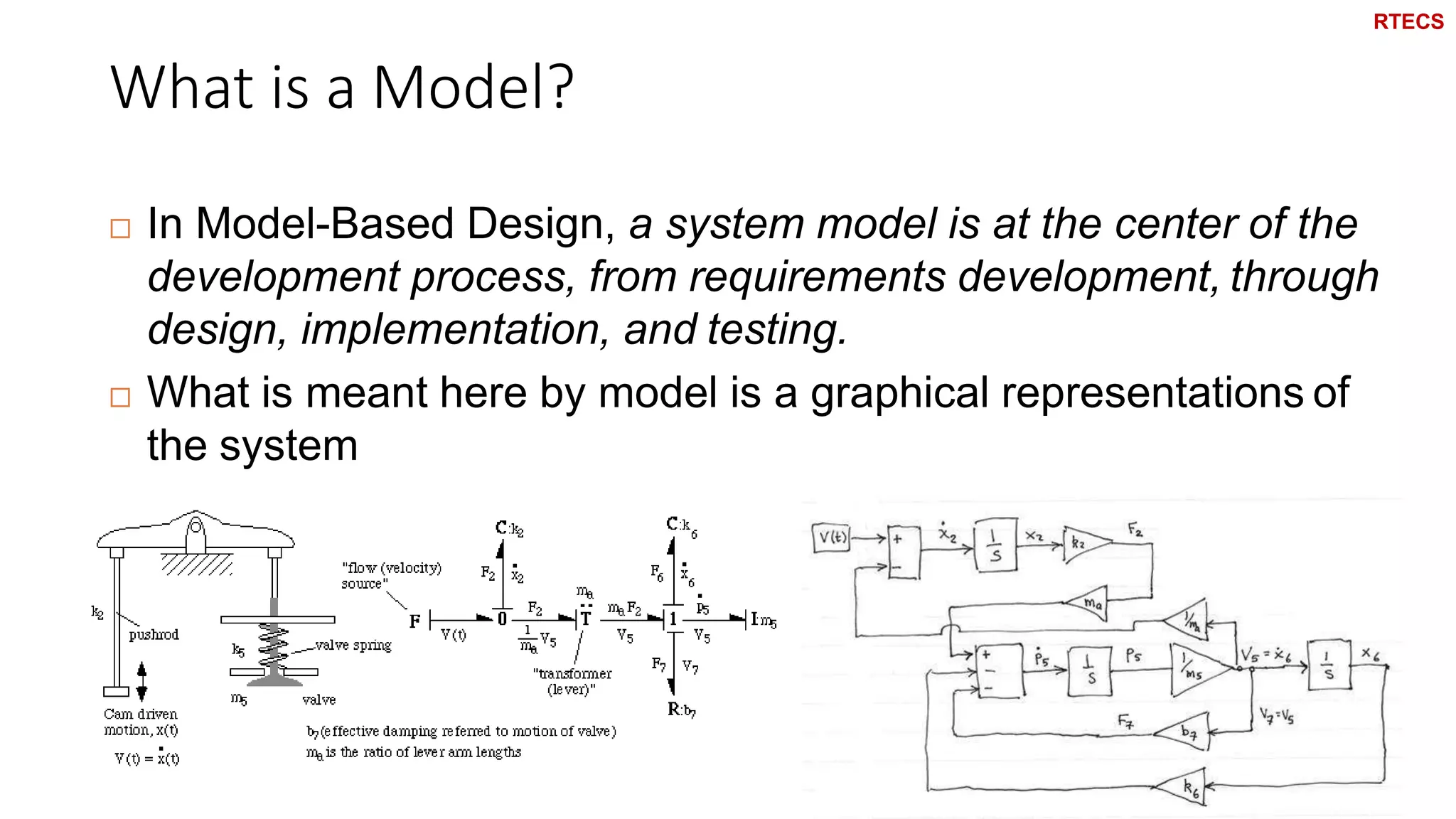

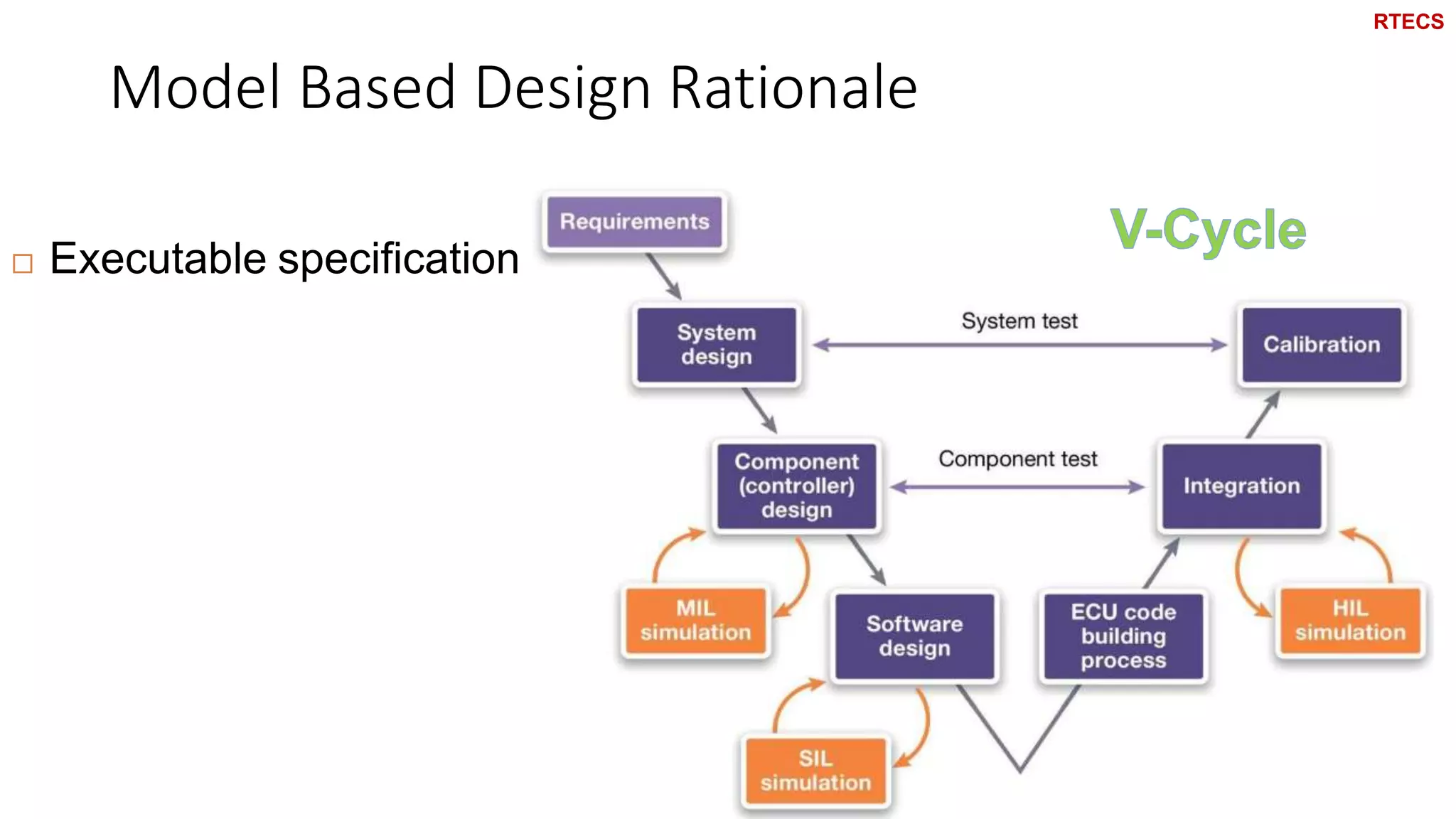

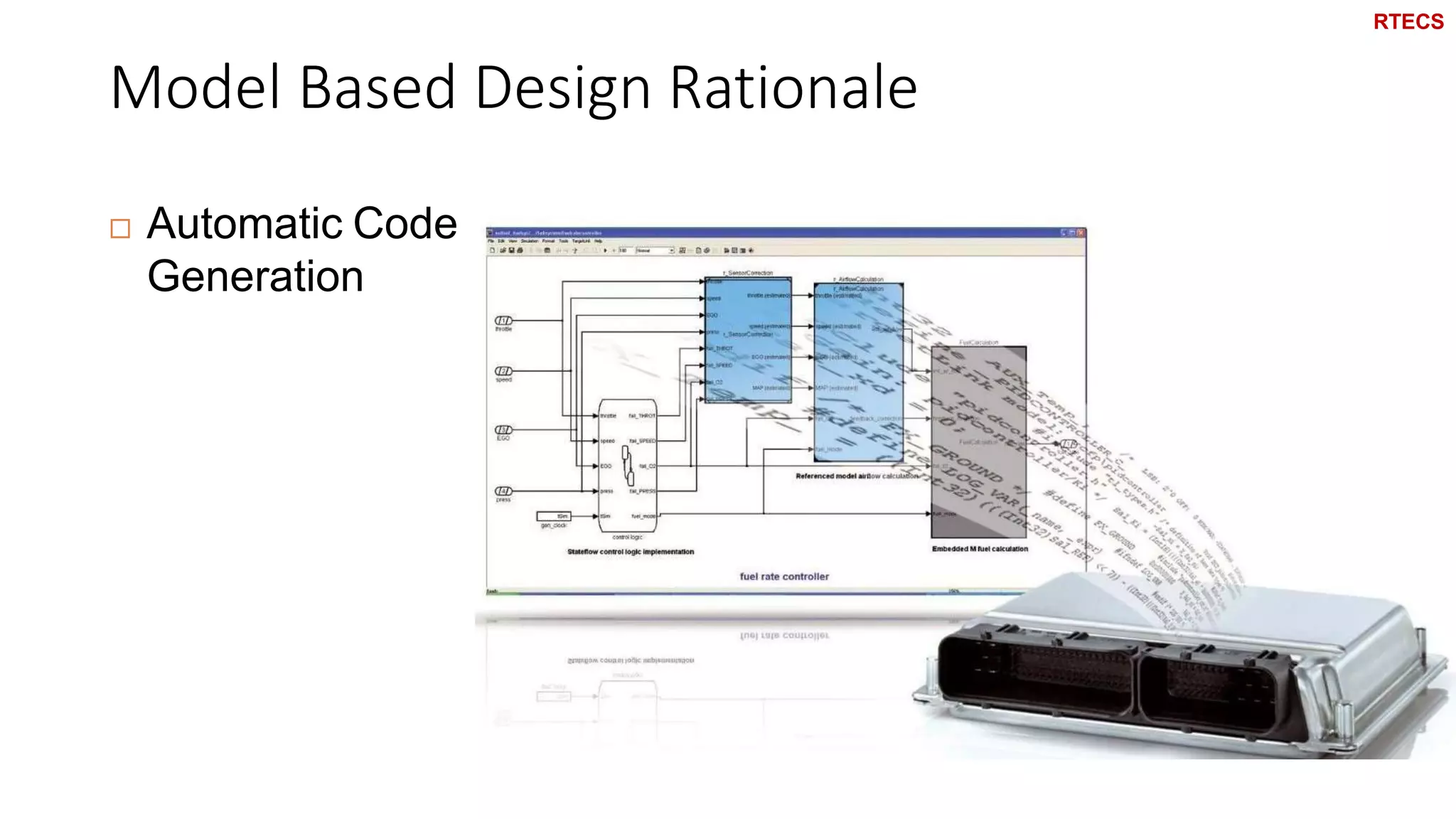

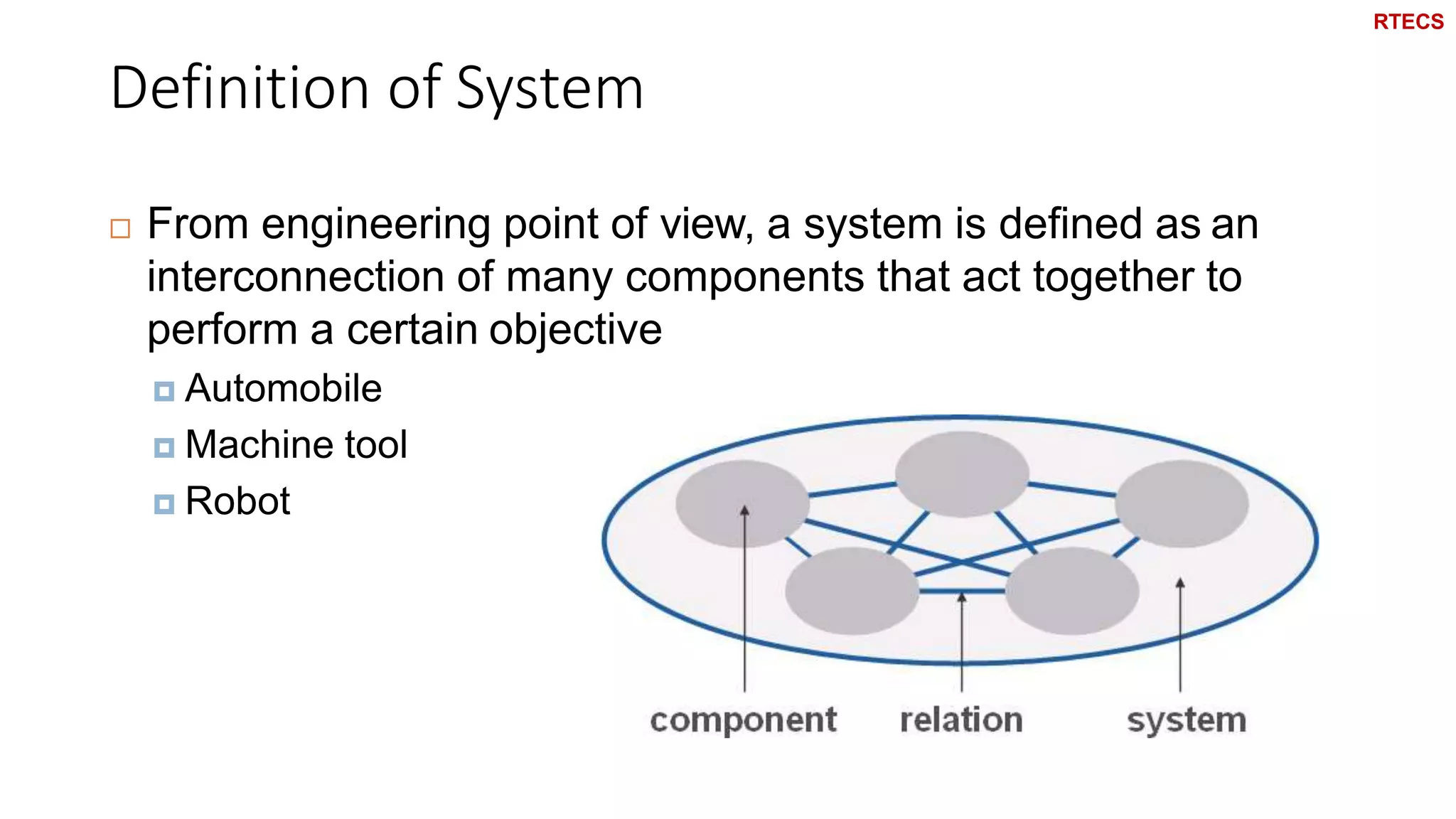

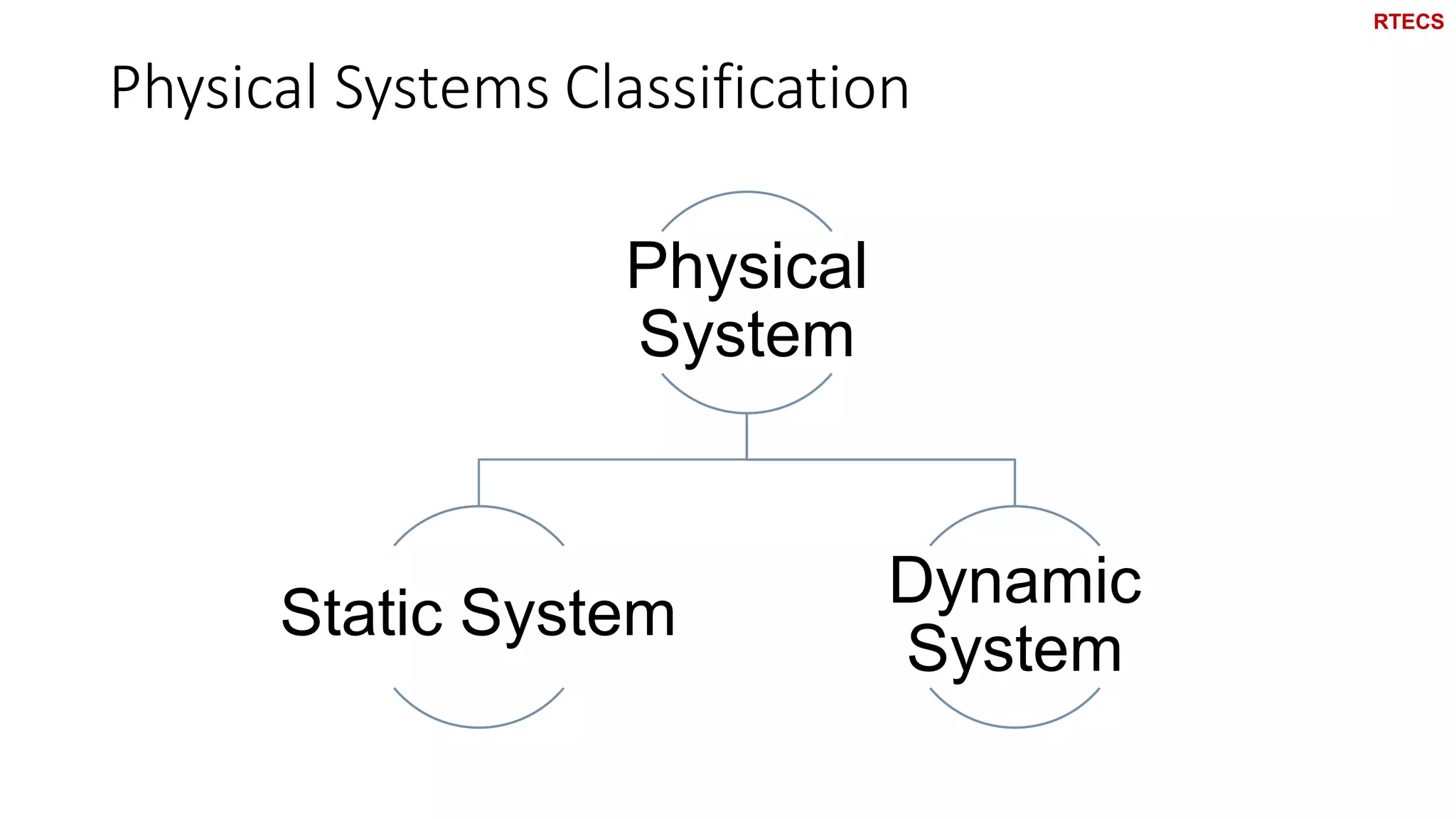

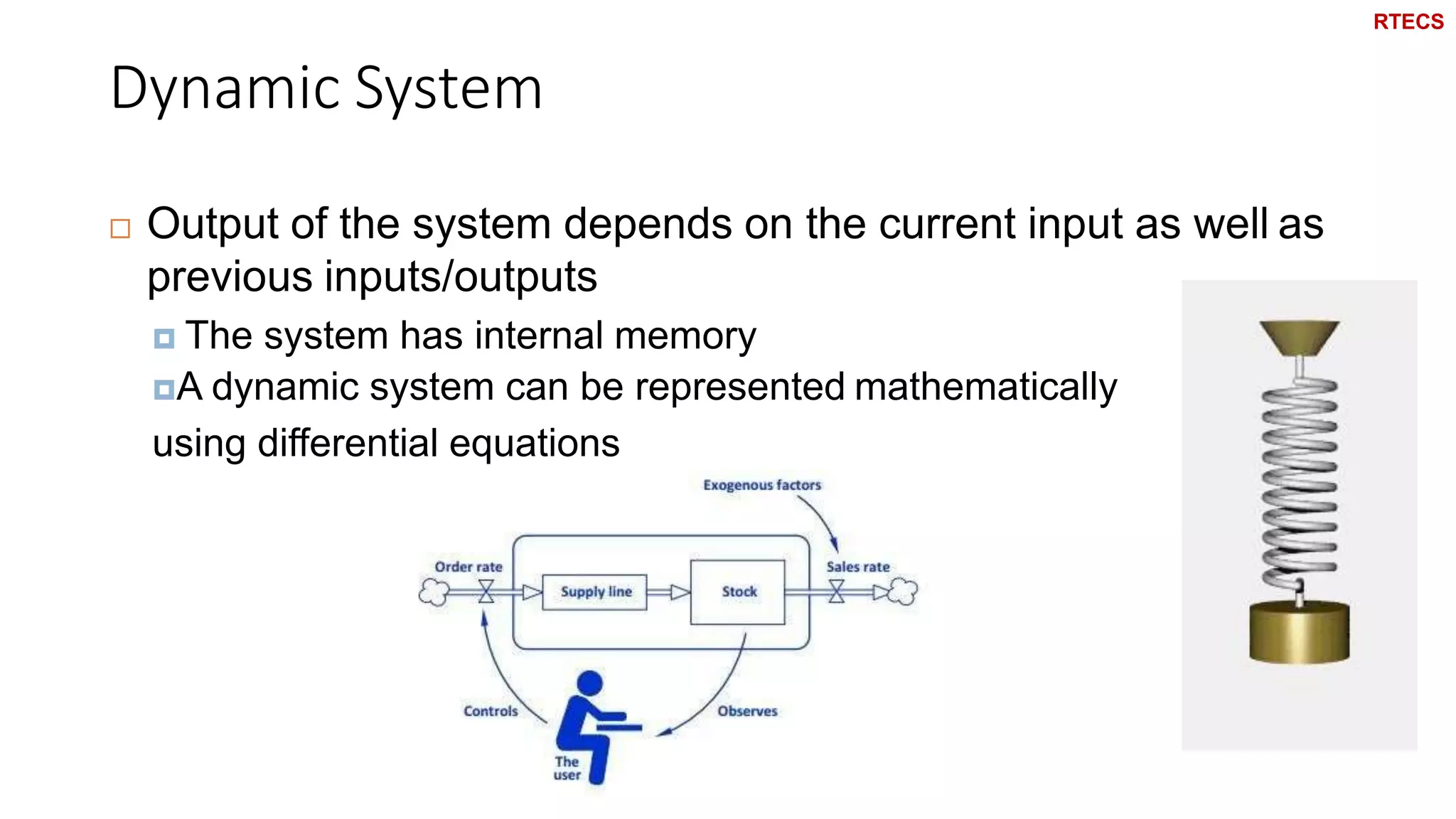

This document provides an overview of a course on real time embedded control systems using model based design concepts. The course aims to show a design path for real time embedded systems starting with system level simulation and ending with real time implementation of control algorithms. It covers topics such as MATLAB and Simulink, physical system modeling, control systems design, embedded coding, and state machines. Model based design is emphasized, with a graphical model at the center of the development process from requirements to testing.