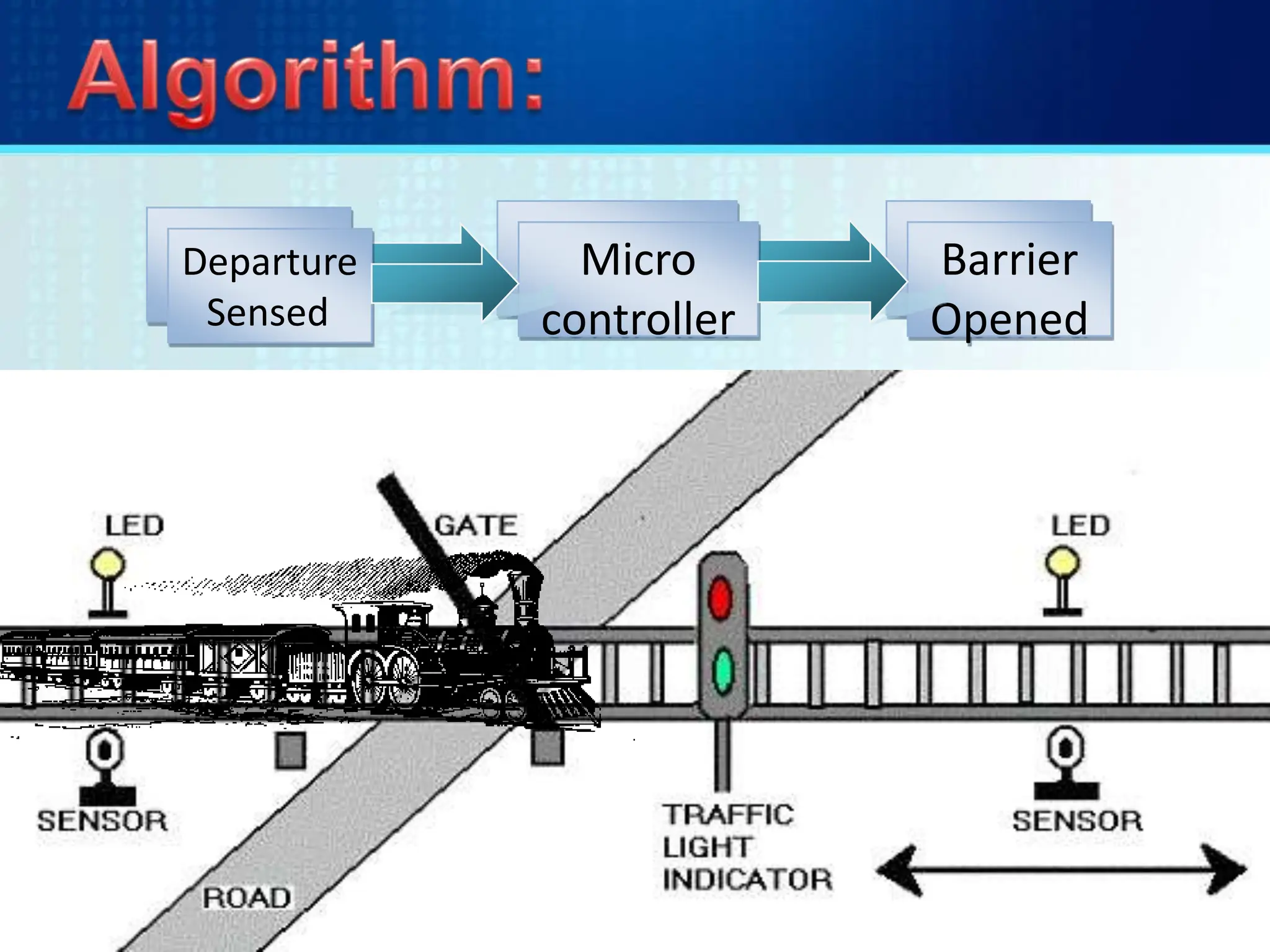

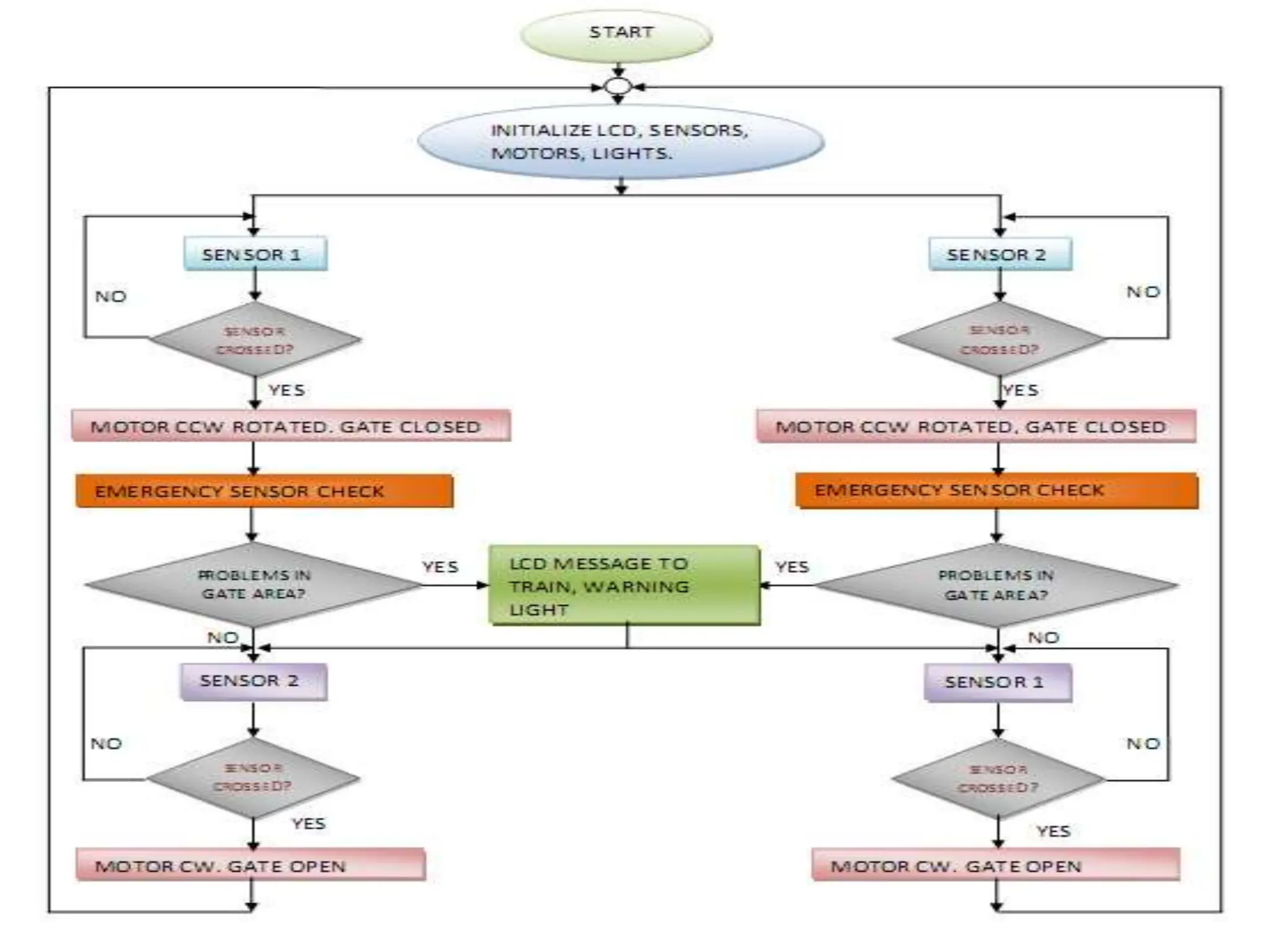

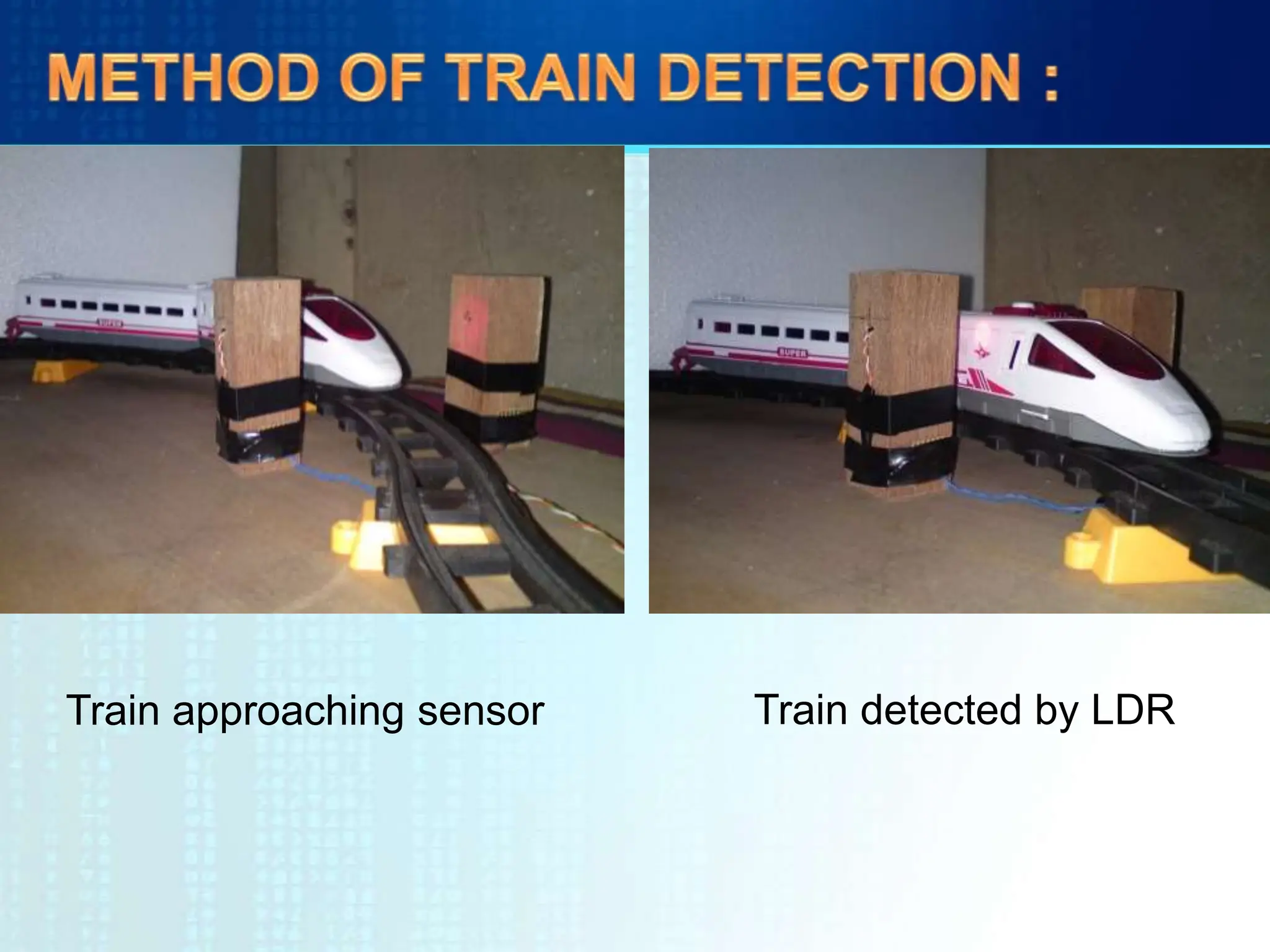

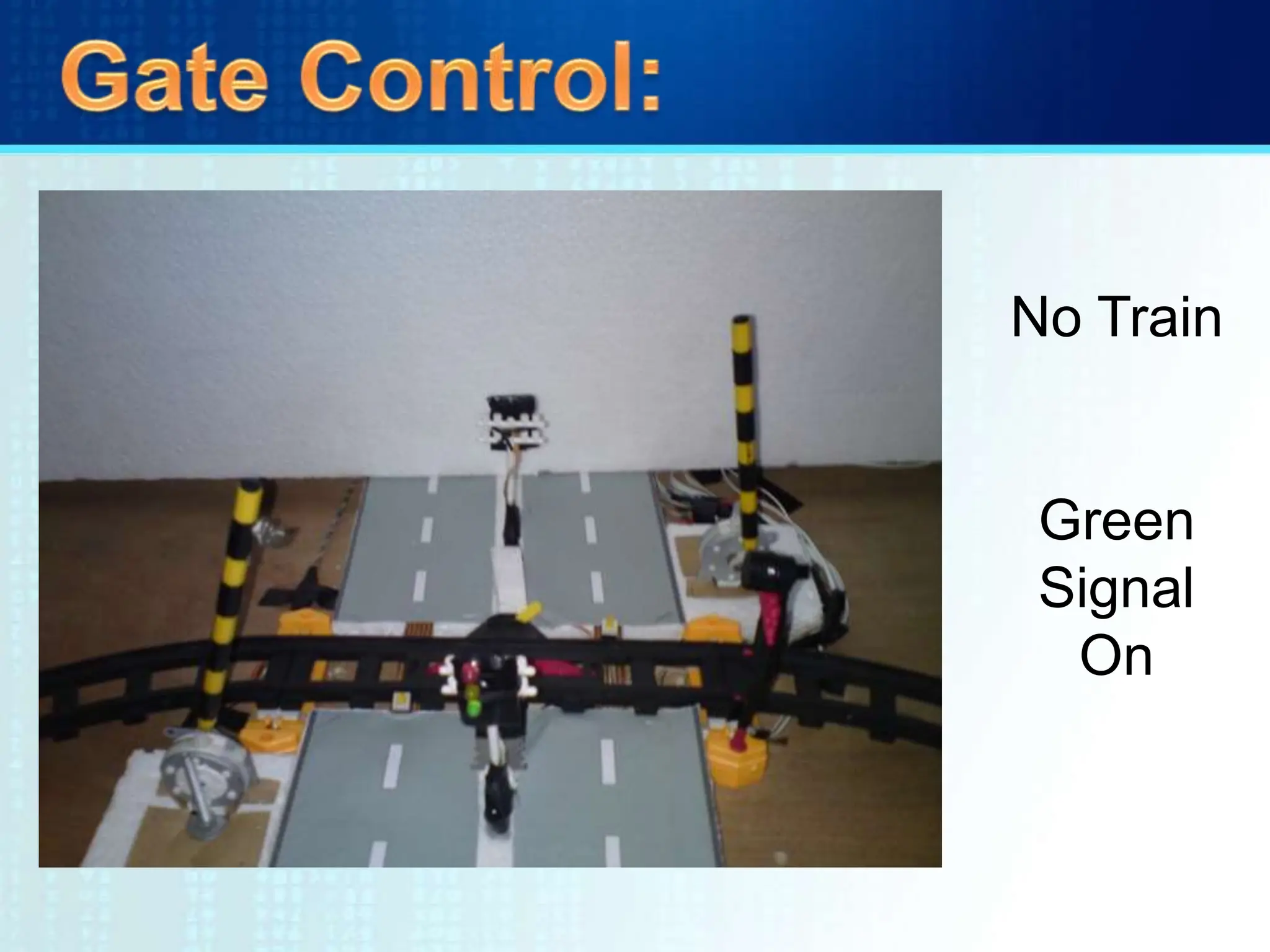

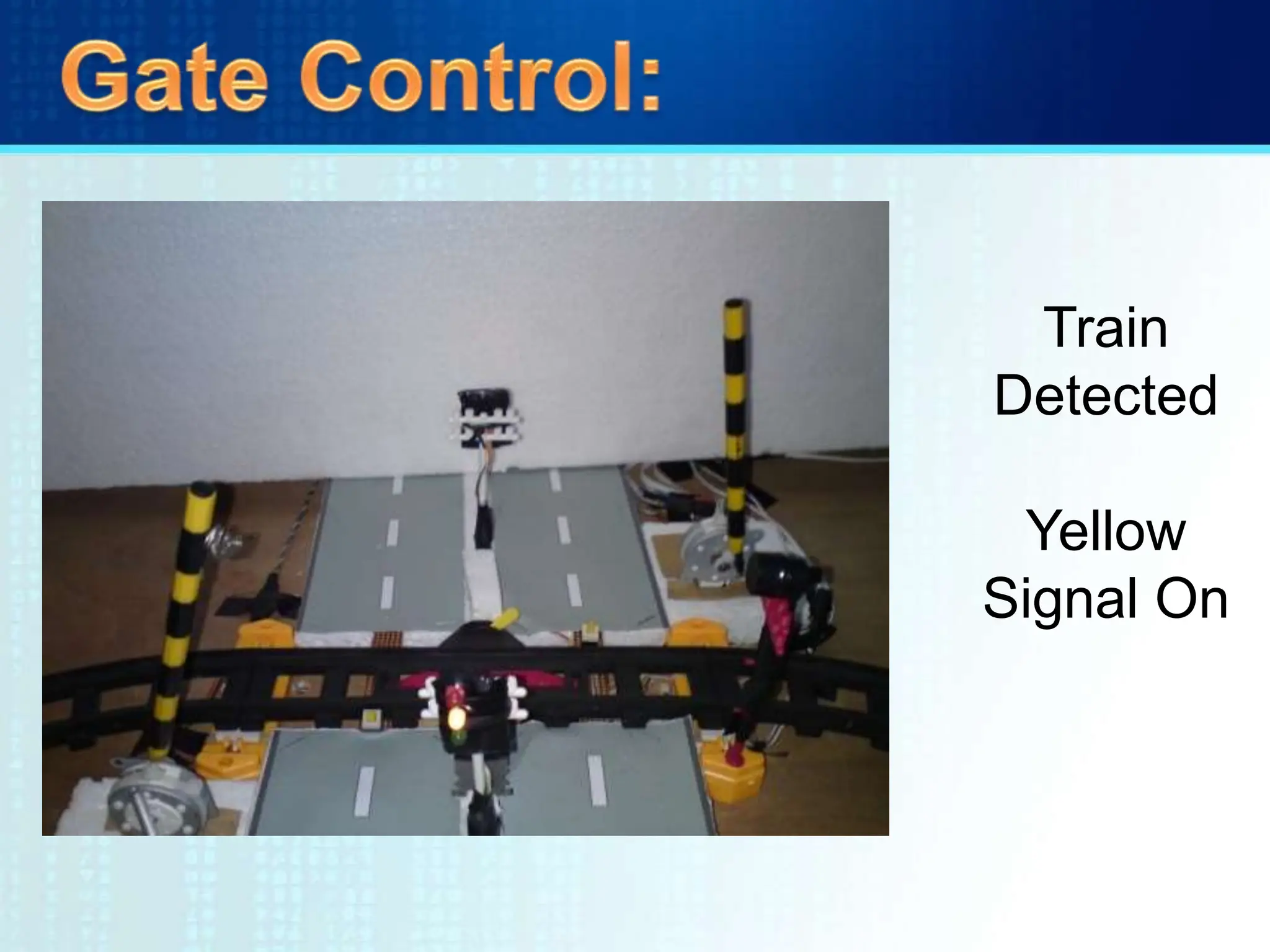

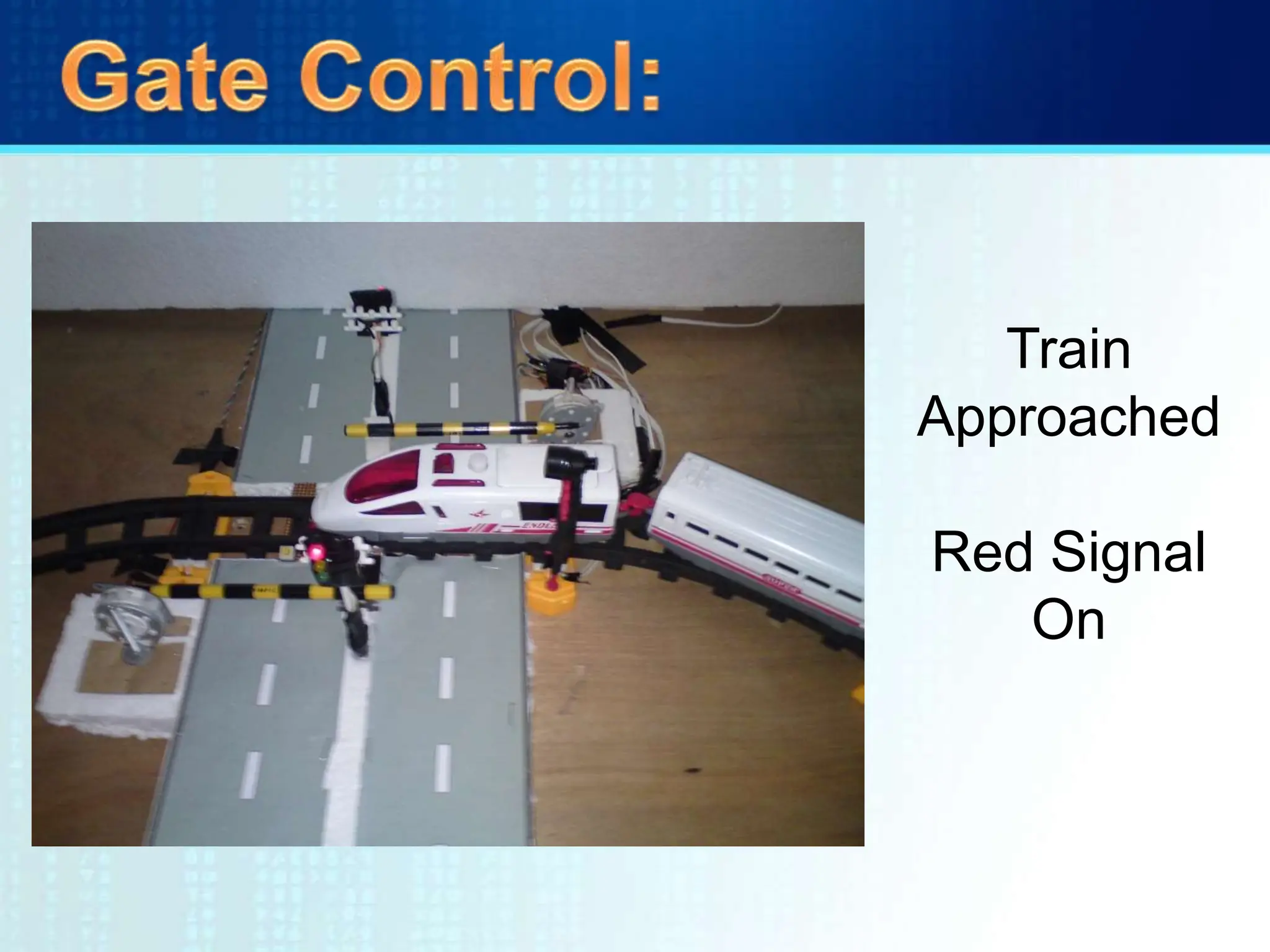

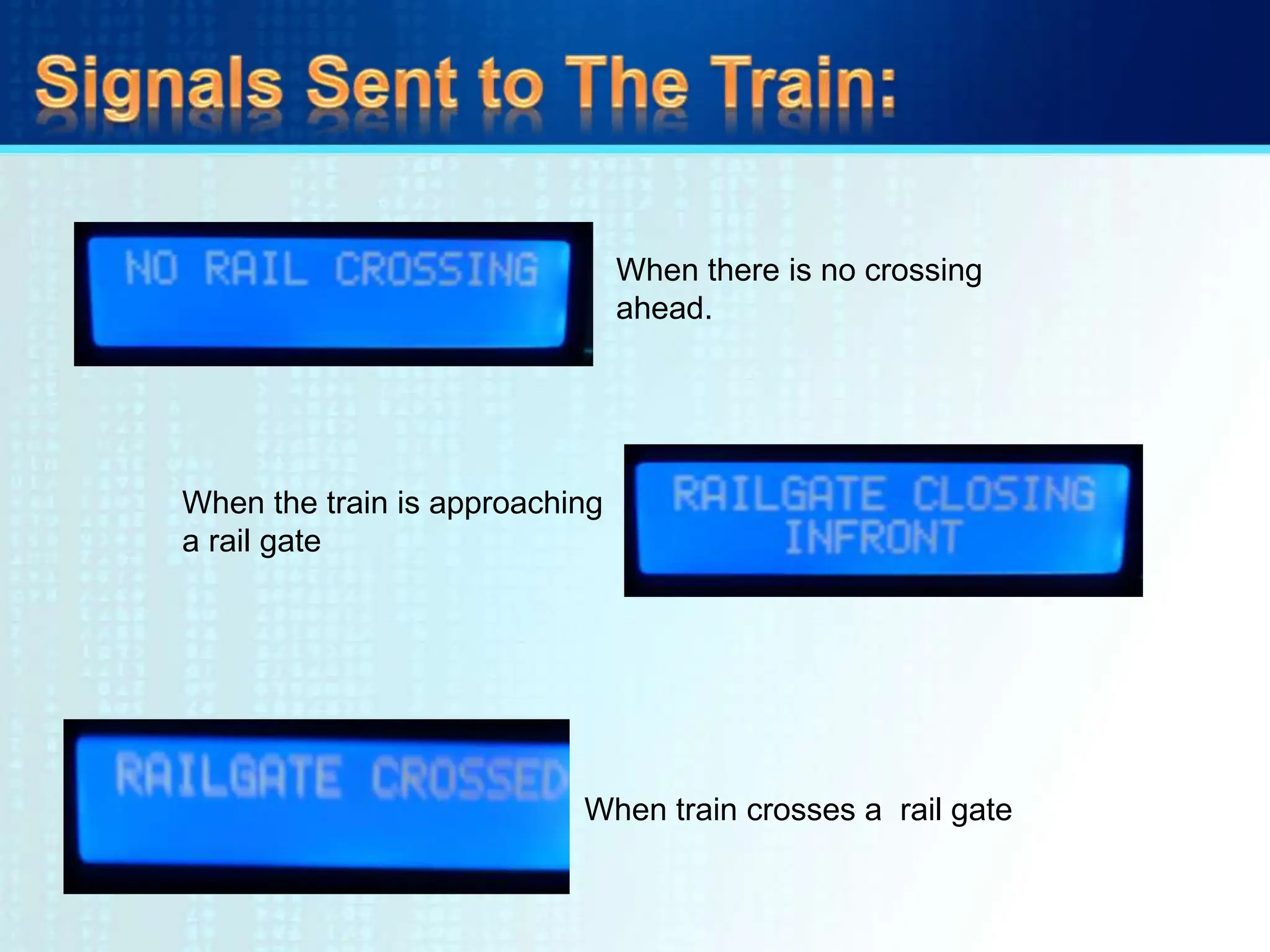

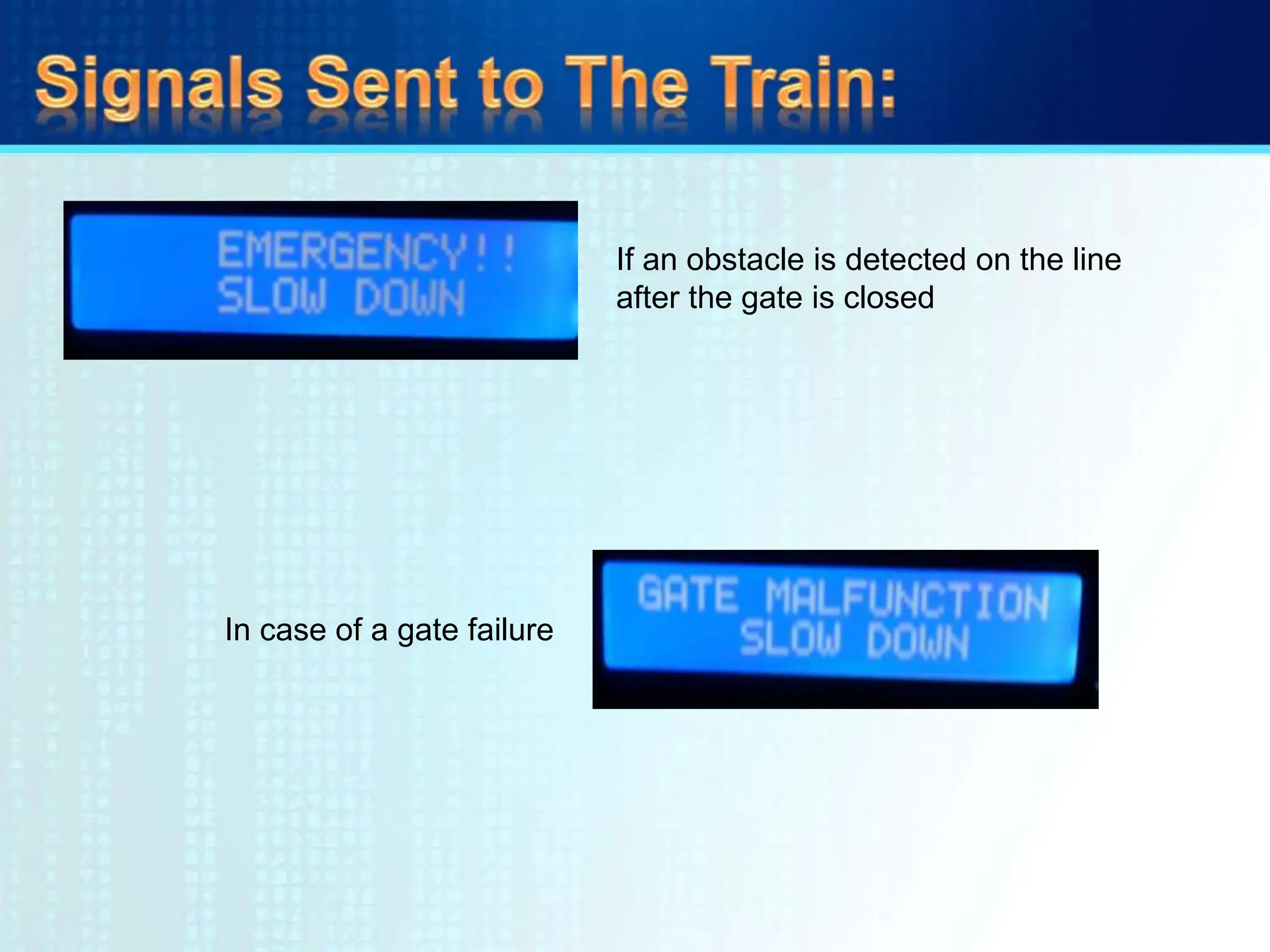

The project aims to design an automatic railway crossing system to enhance safety and efficiency by eliminating manual operations. The system uses sensors to detect approaching trains, automatically closing the gate and reopening it once the train departs, thereby reducing human error and improving time management. Key components include microcontrollers, sensors, and motors for reliable functionality.